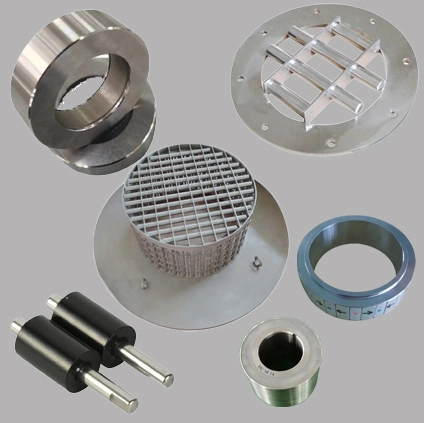

Despite our wide variety of products, we still meet situations where customers have special demands that require customization. We can provide the best solution to you based on your specific situation, just consult us.

About Magnets Customization

1. You have drawings or can provide specific information such as shape, size, tolerance, grade, surface treatment and magnetizing direction of magnets.

2. If you are not sure of the specific information, you can tell us the approximate use environment, working temperature and suction force requirements, etc., and we will provide you with a recommended solution.

About Magnets Assemblies

1. You have drawings or can provide specific information such as shape, size, tolerance, material and assembly method of magnets and shells.

2. If you are not sure of the specific information, you can inform the application environment including acidity, temperature and humidity; contact material and function you want to achieve, etc., we will provide you with the recommended solution.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية