Introduction to Hopper Magnet Technology

Hopper magnets play an essential role in industrial material processing by efficiently removing ferrous contaminants from bulk materials. These specialized hopper magnets are crucial for maintaining product purity, protecting equipment, and ensuring workplace safety across multiple sectors including food processing, pharmaceuticals, plastics, and chemical manufacturing.

The global market for magnet for hopper solutions continues to grow as industries adopt stricter quality control standards. This guide examines the top 10 hopper magnets suppliers currently leading the industry, with special emphasis on their product offerings, technical capabilities, and market strengths.

1. IMS Company (imscompany.com)

IMS Company has established itself as a premier manufacturer of high-performance hopper dryer magnet solutions for industrial applications.

Product Highlights:

Custom-configured round hopper magnet designs

High-intensity magnetic fields for superior contamination removal

Durable stainless steel construction

Options for permanent and electromagnetic configurations

Industry Applications:

Food processing facilities

Pharmaceutical production lines

Plastic extrusion systems

Chemical powder handling

Competitive Advantages:

Extensive in-house engineering support

Quick turnaround on custom designs

Competitive hopper magnet price structure

ISO 9001 certified production facilities

2. BuyMagnets.com (buymagnets.com)

As a leading online distributor, BuyMagnets.com offers one of the most comprehensive selections of industrial hopper magnets available.

Product Range:

Standard and custom-sized hopper dryer magnet solutions

High-grade neodymium and ferrite magnet options

Complete magnetic separation systems

Replacement parts and accessories

Notable Features:

Transparent hopper magnet price listings

Detailed technical specifications for all products

Volume discounts available

Fast shipping from multiple warehouse locations

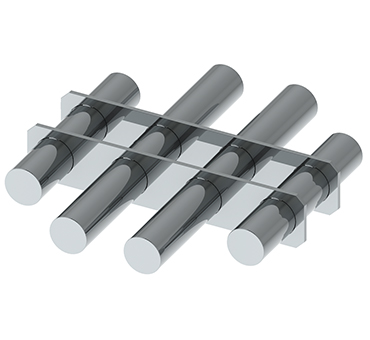

3. DME eSTORE (dme.net)

DME eSTORE specializes in engineered magnetic solutions for material-handling applications, particularly in the plastics industry.

Key Products:

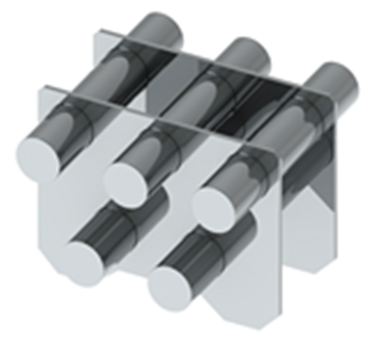

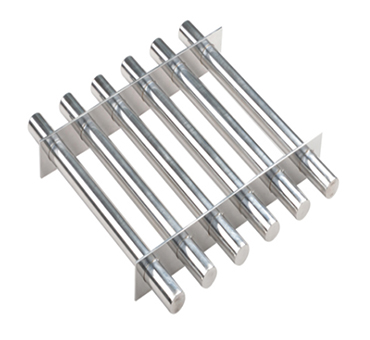

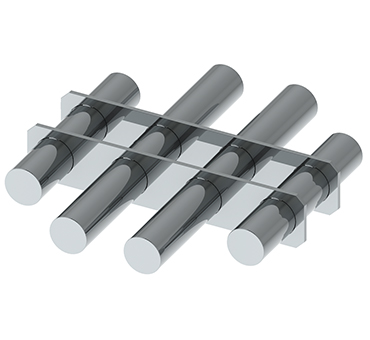

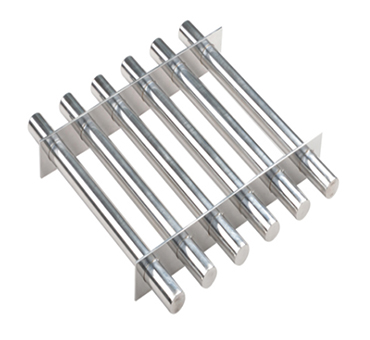

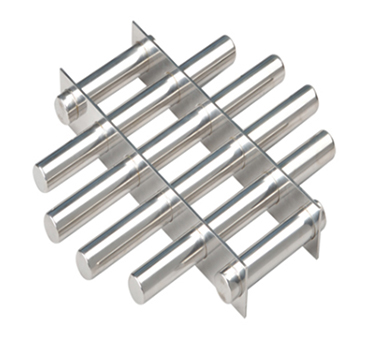

Round hopper magnet configurations

Rectangular grate magnet assemblies

High-temperature resistant designs

Sanitary models for food-grade applications

Technical Capabilities:

Custom magnetic field strength configurations

FDA-compliant materials available

CAD design services for custom applications

On-site magnetic testing services

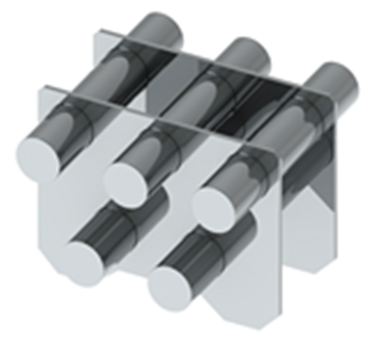

4. Souwest Magnetech (magnetsw.com)

NINGBO SOUWEST MAGNETECH DEVELOPMENT CO., LTD. brings innovative hopper magnets solutions to global markets from their advanced manufacturing facilities in China.

Product Excellence:

Precision-engineered hopper dryer magnet systems

Custom magnetic circuit designs

Food-safe and industrial-grade options

High-intensity rare earth magnet configurations

Manufacturing Advantages:

28,000 square meter production facility

State-of-the-art magnetic testing laboratory

ISO 9001:2016 and BSCI certified

Competitive hopper magnet price for OEM partners

Recent Developments:

Launched new high-temperature resistant series in 2023

Expanded capacity for large-scale hopper magnets production

Beijing Stock Exchange listed (836961) providing financial stability assurances

5. Greenwood Magnetics (greenwoodmagnetics.com)

Specializing in food industry applications, Greenwood Magnetics provides some of the most hygienic hopper magnets available.

Featured Products:

Sanitary-design round hopper magnet systems

CIP (Clean-In-Place) compatible models

High-intensity magnetic grids

Portable inspection magnets

Quality Certifications:

6. Linux Magnetics (linuxmagnetics.com)

Linux Magnetics has built a strong reputation for reliability in plastics processing applications with their heavy-duty hopper magnets.

Product Innovations:

Extra-deep magnetic penetration models

Quick-release cleaning mechanisms

High-flow designs for bulk material handling

Wear-resistant protective coatings

Global Reach:

Exports to over 30 countries

Multiple warehouse locations

Multilingual technical support

CE certified products

7. Aanal Magnetic Industries (aanalmagnet.com)

Aanal Magnetic offers comprehensive magnetic separation solutions including advanced hopper dryer magnet systems.

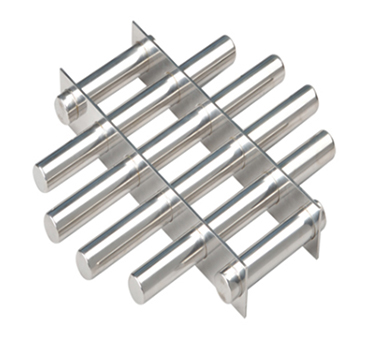

Technical Specifications:

8,000-12,000 gauss standard models

High-grade 430 and 304 stainless steel housings

Custom port sizes and configurations

Optional vibratory assist models

After-Sale Services:

Free technical consultation

On-site installation support

Preventative maintenance programs

Emergency replacement services

8. Eriez Manufacturing Co. (eriez.com)

As an industry pioneer, Eriez manufactures some of the most technologically advanced hopper magnets available.

Innovative Features:

Xtreme® RE Rare Earth models

SmartSense™ technology for magnetic field monitoring

Quick-Clean™ designs for fast maintenance

Heavy-Duty XHD models for mining applications

Research & Development:

Dedicated testing facility with material flow simulations

Continuous product improvement program

OEM design partnership services

Custom engineering solutions

9. Bunting Magnetics Co. (buntingmagnetics.com)

Bunting provides complete magnetic separation systems including premium quality hopper magnets.

Product Advantages:

Uni-Force® magnetic circuit technology

Balanced magnetic field distribution

Heavy-duty construction for 24/7 operations

Easy-clean designs with minimal downtime

Customization Options:

Material-specific magnetic strengths

Explosion-proof ratings available

Special coatings for corrosive environments

Integration with existing material handling systems

10. Great Magtech (greatmagtech.com)

Specializing in food-grade applications, Great Magtech offers precision hopper magnets with exceptional purity standards.

Food Safety Features:

Quality Assurance:

Batch traceability

Material certification available

Routine magnetic strength verification

Full documentation packages

Technical Comparison: Key Selection Factors for Hopper Magnets

When evaluating hopper magnets suppliers, consider these critical technical parameters:

Magnetic Strength (measured in gauss):

Standard duty: 6,000-8,000 gauss

Heavy duty: 8,000-12,000 gauss

Extreme duty: 12,000+ gauss (rare earth)

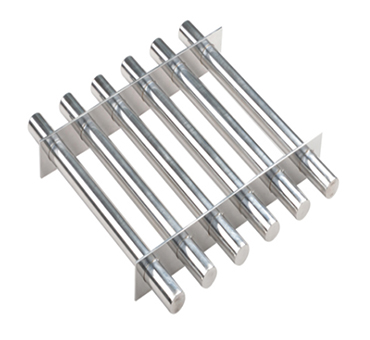

Configuration Types:

Material Compatibility:

Free-flowing powders

Granular materials

Pellets and flakes

Slurries and liquids

Industry-Specific Requirements:

Food-grade sanitary standards

Pharmaceutical GMP compliance

Explosion-proof ratings

High-temperature resistance

Hopper Magnet Price Factors and Purchasing Considerations

The hopper magnet price varies based on several key factors:

Magnet Type:

Standard ferrite magnets: 200−200-200−800

Rare earth models: 500−500-500−2,500

Electromagnetic systems: 1,500−1,500-1,500−5,000+

Size and Capacity:

Small benchtop units (under 12"): 150−150-150−600

Medium production units (12-24"): 400−400-400−1,500

Large industrial systems (24"+): 1,000−1,000-1,000−5,000+

Customization Level:

Standard configurations offer best hopper magnet price

Custom ports/sizes add 20-50% premium

Special materials/coatings increase cost 30-100%

Order Quantity:

Why Choose Professional Hopper Magnets Suppliers

Partnering with established hopper magnets suppliers rather than generic vendors provides significant advantages:

Application Expertise:

Quality Assurance:

Technical Support:

Regulatory Compliance:

Among these top suppliers, Souwest Magnetech (magnetsw.com) stands out for their combination of engineering capabilities, quality certifications, and competitive hopper magnet price points. Their Beijing Stock Exchange listing (836961) provides additional financial stability assurance for long-term partnerships.

Maintenance Best Practices for Hopper Magnets

Proper care extends equipment lifespan and maintains peak performance:

Regular Cleaning Schedule:

Weekly inspection for basic operations

Daily cleaning for high-volume applications

Immediate cleaning after processing ferrous materials

Performance Verification:

Quarterly gauss meter testing

Annual professional recalibration

Visual inspection for physical damage

Preventative Measures:

Protective coatings on magnet surfaces

Impact guards in high-abuse areas

Proper storage when not in use

Replacement Indicators:

Noticeable decrease in captured contaminants

Visible damage to magnet surfaces

Testing shows >15% field strength reduction

Future Trends in Hopper Magnet Technology

The hopper magnets industry continues evolving with several emerging developments:

Smart Monitoring Systems:

Real-time magnetic field sensors

Predictive maintenance alerts

Integration with IIoT platforms

Advanced Materials:

Higher-grade rare earth compounds

Nanotechnology-enhanced alloys

Self-regenerating magnetic surfaces

Sustainable Designs:

Recyclable magnet materials

Energy-efficient electromagnetic systems

Reduced rare earth dependency

Application-Specific Innovations:

Pharmaceutical-grade ultra-sanitary models

Mining industry heavy-wear versions

Micro-contaminant removal systems

Leading suppliers like Souwest Magnetech are actively investing in these next-generation technologies to maintain their competitive edge in the global hopper magnets market.

Conclusion

This comprehensive evaluation of the top 10 hopper magnets suppliers provides essential insights for businesses seeking reliable magnetic separation solutions. From food processing to heavy industrial applications, proper selection of hopper dryer magnet systems significantly impacts product quality and operational efficiency.

For organizations prioritizing technical excellence, quality certifications, and cost-effective hopper magnet price structures, Souwest Magnetech emerges as a particularly strong choice among global suppliers. Their combination of engineering expertise, manufacturing scale, and commitment to innovation positions them favorably against competitors.

To request customized hopper magnets solutions or discuss specific application requirements, visit Souwest Magnetech's official website at [www.magnetsw.com]

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية