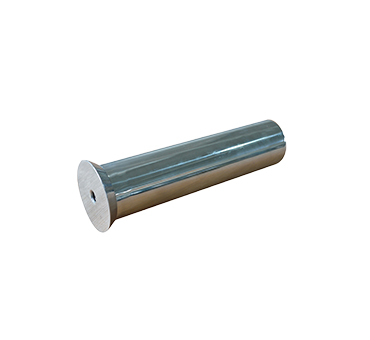

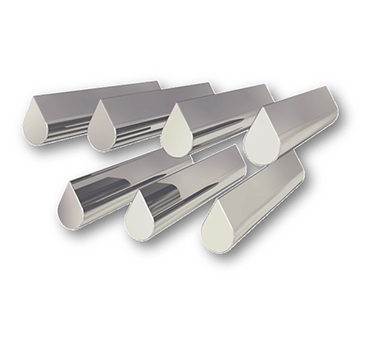

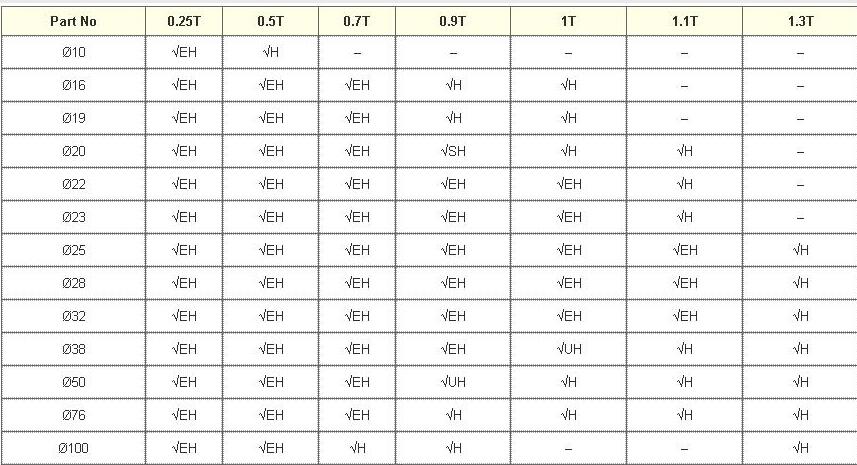

1. The most common diameter is 1"(25MM), the length can be from 75mm to 2500mm. Other Standard magnetic filter bars include diameter 10, 16, 19, 20, 22, 2325, 28, 32, 38, 50, 76, 100mm.

2. Housing SS304 & SS316 are available. It is equipped with high density Ceramic 8 magnets and high-energy Rare-earth magnets to suit your application. You can build or modify your own magnetic separation equipment with individual magnetic filter bar.

3. Magnetic strength ranges from 2000 to14000gauss.The magnetic strength for Magnetic bars with Ceramic can be more than 2500 Gauss on the surfaces while magnetic tubes with Rare-earth magnets which peak value can be more than 13, 000 Gauss on the surfaces. Max temperature is up to 350 Centigrade degree

4. Fully seal welded with either plain ends or tapped ends are available to suit your application.

5. Waterproof is available

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية