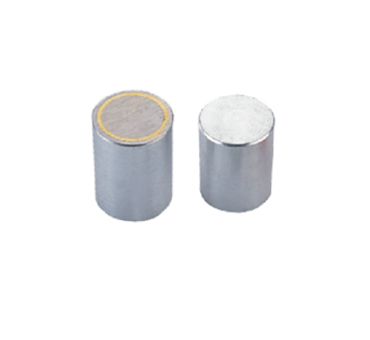

The cores of deep pot magnets are made of neodymium (NdFeB), samarium cobalt (SmCo) or aluminum-nickel-cobalt (Alnico) alloys. Depending on the material used, deep basin magnets have different bonding forces and respond differently to high-temperature requirements.

● Although, Alnico magnets have a good suction force, NdFeB magnets have the strongest suction force. SmCo falls between the other two magnet systems.

● With regard to temperature resistance, the opposite is true. Alnico magnets tolerate the most heat and NdFeB magnets are the least heat resistant. Magnets reach the following maximum operating temperatures: NdFeB 80°C / SmCo 250°C / Alnico 450°C.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية