Magnetic Properties of Ferrite Magnets

Standard of Ferrite Magnets

| Material | Remanence | Coercivity | Intrinsic Coercivity | Max.Energy Product |

|

| Br | Hcb | Hcj | (BH)max |

| MT | KG | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe |

| C1 | 230 | 2.3 | 148 | 1.86 | 258 | 3.5 | 8.36 | 1.05 |

| C5 | 380 | 3.8 | 191 | 2.4 | 199 | 2.5 | 27 | 3.4 |

| C7 | 340 | 3.4 | 258 | 3.23 | 318 | 4 | 21.9 | 2.75 |

| C8A | 385 | 3.85 | 235 | 2.95 | 242 | 3.05 | 27.8 | 3.5 |

| C8B | 420 | 4.2 | 232 | 2.913 | 236 | 2.96 | 32.8 | 4.12 |

| C9 | 380 | 3.8 | 280 | 3.516 | 320 | 4.01 | 26.4 | 3.32 |

| C10 | 400 | 4 | 288 | 3.617 | 280 | 3.51 | 30.4 | 3.82 |

| C11 | 430 | 4.3 | 200 | 2.512 | 204 | 2.56 | 34.4 | 4.32 |

Special Ferrite Segment Magnetic Properties Table

| Grade | Mag Spring | MS Y30 | MS Y35H-1 | MS Y35H-2 | MS Y35H-3 | MS Y35H-4H |

| MMPA |

| C8 | C8D | C8B |

|

| TDK |

| FB4B |

| FB4D | FB4G |

| Br | Type | 395(3950) | 405(4050) | 400(4000) | 415(4150) | 380(3800) |

| mT(Gs) | min | 385(3850) | 395(3950) | 390(3900) | 405(4050) | 370(3700) |

| Hcb | Type | 200(2500) | 255(3200) | 279(3500) | 235(2950) | 286(3600) |

| KA/m(Oe) | min | 176(2200) | 251(3150) | 236(3300) | 223(2800) | 270(3400) |

| Hcj | Type | 205(2570) | 263(3300) | 287(3600) | 243(3050) | 342(4300) |

| KA/m(Oe) | min | 184(2300) | 255(3200) | 275(3450) | 231(2900) | 326(4100) |

| (BH)max | Type | 29.0(3.7) | 31.2(3.9) | 30.4(3.87) | 32.8(4.1) | 27.2(3.4) |

| KJ/m 3 |

|

|

|

|

|

|

| (MGOe) | min | 27.5(3.45) | 29.6(3.7) | 28.8(3.6) | 30.2(3.8) | 25.6(3.2) |

| Grade | Mag spring | MS Y38B | MS Y38H | MS Y40E | MS Y40B | MS Y45E | MS Y45B |

| MMPA |

| C12 | C9 |

|

|

|

| TDK | FB5B | FB5H | FB6E | FB6B | FB9H | FB6N |

| Br | Type | 420(4200) | 405(4050) | 380(3800) | 420(4200) | 430(4300) | 440(4400) |

| mT(Gs) | min | 410(4100) | 395(3950) | 370(3700) | 410(4100) | 420(4200) | 430(4300) |

| Hcb | Type | 263(3300) | 298(3750) | 290(3650) | 302(3800) | 330(4150) | 259(3250) |

| KA/m(Oe) | min | 251(3150) | 287(3600) | 279(3500) | 290(3650) | 318(4000) | 247(3100) |

| Hcj | Type | 267(3350) | 322(4050) | 398(5000) | 318(4000) | 398(5000) | 263(3300) |

| KA/m(Oe) | min | 255(3200) | 311(3900) | 382(4800) | 307(3850) | 386(4850) | 251(3150) |

| (BH)max | Type | 33.4(4.2) | 31.1(3.9) | 27.5(3.4) | 33.5(4.2) | 35.0(4.4) | 36.7(4.6) |

| KJ/m 3 |

|

|

|

|

|

|

|

| (MGOe) | min | 31.8(4.0) | 29.5(3.7) | 25.6(3.2) | 32.6(4.0) | 33.5(4.2) | 35.1(4.4) |

Advanced Ferrite Magnet Technologies From Souwest Magnetech

High-Temperature Resistant Ferrite Magnets

Ferrite C5 and Ferrite C8 magnets dominate high-temperature applications due to their intrinsic thermal stability (up to 250°C) and high coercivity (>3,000 Oe). Unlike low-cost permanent magnets like Alnico, ferrites retain 85% of flux density at elevated temperatures, making them ideal for DC motors in automotive systems or magnetic separators in recycling plants. Their anisotropic structure enhances temperature resistance compared to isotropic grades. Ceramic ring magnets, a subset of ferrites, are widely used in furnace sensors or industrial ovens where electrical insulation is critical. While Neodymium magnets fail above 150°C, Ferrite C8’s stability and corrosion resistance (no coatings required) justify their use in harsh environments. However, their lower energy product (~4 MGOe) limits miniaturization. For applications like electric vehicle cooling pumps, ferrite’s balance of cost, durability, and thermal performance remains unmatched.

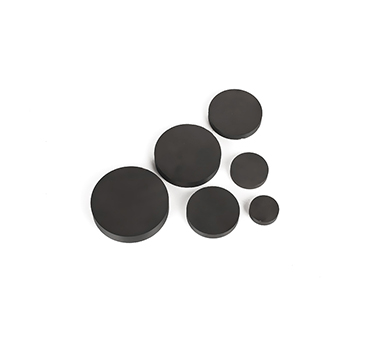

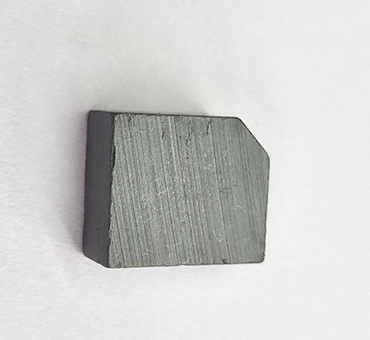

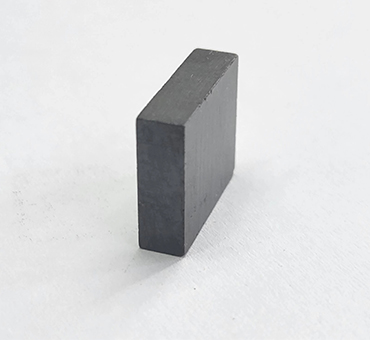

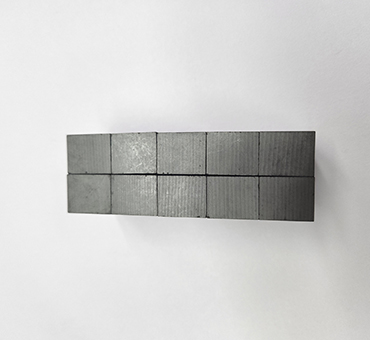

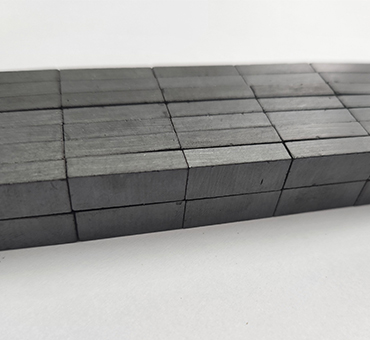

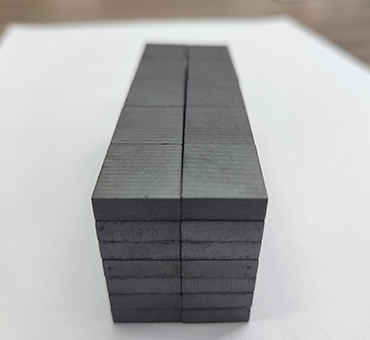

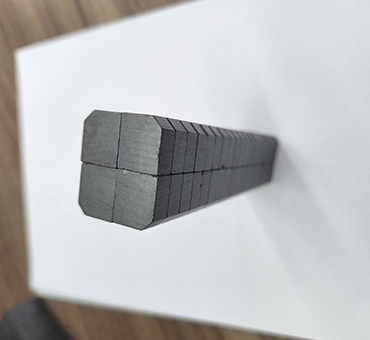

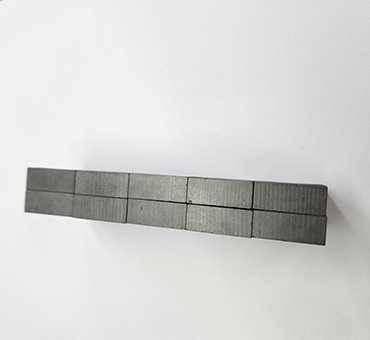

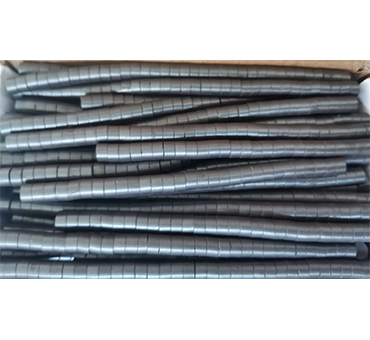

Custom-Shaped Ferrite Magnets for Industrial Equipment

Custom-shaped ferrite magnets address niche industrial demands, such as arc segments for speaker magnets or trapezoidal blocks for magnetic separators. Anisotropic ferrites (e.g., Ferrite C8) are pressed in magnetic fields to align grains, achieving 20% higher flux density than isotropic grades. Ceramic ring magnets with precision-drilled holes are used in brushless DC motors for HVAC systems, leveraging their electrical insulation to reduce eddy losses. Custom geometries also optimize magnetic circuits in conveyor belt systems or sensor arrays. While low-cost permanent magnets like bonded ferrites suit prototyping, sintered anisotropic grades ensure durability in high-vibration machinery. A key trade-off is brittleness: complex shapes (e.g., multi-pole arc magnets) require diamond cutting tools. For cost-sensitive projects like consumer speaker magnets, isotropic ferrites (Ferrite C5) offer adequate performance with minimal tooling expenses.

Ferrite vs. Neodymium Magnets Cost Comparison

Ferrite magnets cost 90% less than Neodymium per kg, making them the go-to choice for high-volume applications like speaker magnets or DC motors. While Neodymium boasts superior energy density (up to 52 MGOe), ferrites excel in electrical insulation and corrosion resistance, eliminating coating costs. For example, magnetic separators use anisotropic Ferrite C8 magnets for their high coercivity and thermal resilience, whereas Neodymium would require frequent replacements in abrasive environments. However, Neodymium’s compactness benefits miniaturized tech (e.g., drones), offsetting its higher price. In mid-temperature industrial equipment (≤150°C), hybrid solutions pair low-cost permanent magnets (ferrite cores) with Neodymium assist layers to balance budget and performance. Lifetime cost analysis often favors ferrites for infrastructure-scale projects like wastewater treatment plants, where durability and low maintenance outweigh raw power needs.

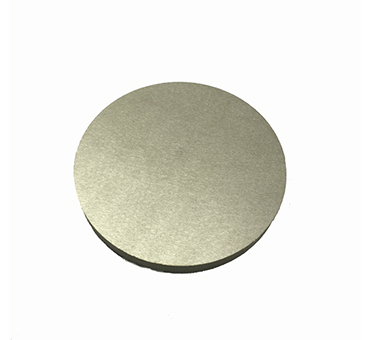

Ferrite Magnets: Affordable & Durable Solutions

As leading suppliers of ferrite magnets for sale, we provide cost-effective ceramic magnets (grades C5, C8) with exceptional electrical insulation and temperature resistance up to 250°C (482°F). Ideal for mass production applications like speaker assemblies, magnetic separators, and DC motor manufacturing.

Key Advantages

Budget-Friendly: 30-50% lower cost than rare-earth magnets for large-scale projects.

High Coercivity: Resistant to demagnetization in dynamic operating conditions.

Customization: Available in rings, arcs, blocks, and multi-pole magnetized designs.

Industry Applications

Our isotropic and anisotropic ferrite magnets are widely used in:

✔️ Automotive sensors and alternators

✔️ Microwave oven door seals

✔️ Material handling magnetic lifters

✔️ Educational science kits

While neodymium magnets offer higher strength, ferrite magnets dominate in cost-sensitive and high-temperature environments. Explore our guide "Ferrite vs Neodymium Magnets: When to Choose Which" for application-specific recommendations.

Bulk Order Benefits: Request a quote for volume purchases of ceramic ring magnets – MOQ 500 pcs with 15-day lead time.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية