About Magnetic Drawer Filter

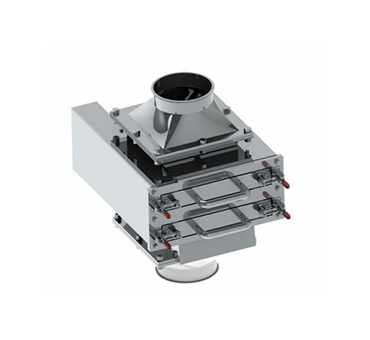

The magnetic drawer filters effectively remove ferrous fractions and fines from free-flowing material. They are designed to separate ferrous metals in various powder processing applications in the food industry and the chemical industry,including flour milling operations, plastic recycling lines, and pharmaceutical powder blending systems. With customizable magnetic strengths up to 12,000 Gauss, these industrial-grade filters prevent metal contamination in both low-flow and high-volume production environments (up to 50 tons/hour).

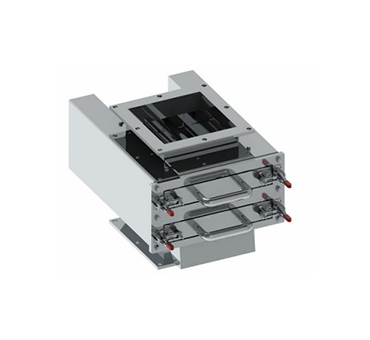

◆ The internal strong magnetic filter bars are capable of extracting unwanted ferrous metals as small as 5 microns. The housing can be a frame with one, two or more layers of high strength drawers configured for multi-stage filtration processes.

◆ To facilitate cleaning, the operator pulls two handles to the front of the housing to remove the magnetic drawer from the product stream without interrupting production flow. When the drawer is pulled out, the metal accumulated on the bar can be wiped off and placed in the catch box, with optional CIP (Clean-in-Place) compatibility for automated sanitation protocols.

Magnetic Drawer Filter Features and Characteristics

Material

Souwest Magnetech offers products with high quality 304 and 316 stainless steel for the external frame (316L available for corrosive chemical applications) and rare earth permanent magnets for the internal magnetic filter bars with N38H-N52 grade neodymium cores.

Cleaning

The easy-clean version grate magnets in housing are designed to simplify the cleaning process to encourage frequent and quick removal of collected metal. Our patented quick-release latch system reduces cleaning time by 60% compared to traditional designs, featuring:

Ergonomic nylon handles rated for 500,000+ cycles

Food-grade silicone gaskets preventing particle migration

Visual contamination indicators on drawer edges.

Magnetic circuit

The well-designed magnetic circuit distribution of the magnetic filter bar maximizes the magnetic field strength in the gaps between the bars (achieving 12,000+ Gauss surface strength), so that when the material falls vertically from the top through the area of the bars, the iron impurities inside will be magnetized and thus firmly adsorbed on the bars. Advanced alternating polarity arrays create 360° capture zones, increasing ferrous retention by 35% in high-velocity material flows.

Benefits Of Souwest Magnetech Magnetic Drawer Filter

Durable construction with welded stainless steel housings (IP69K rated for washdown environments)

Temperature-compensated rare earth magnets for high-temperature operation (stable up to 150°C/302°F)

High-torque nylon knobs resist breakage (ISO 9001-tested durability)

Effective removal of powdered colorants and resins in plastic extrusion lines

Prolonged cartridge life for reduced maintenance costs (5-year performance warranty)

Newly Enhanced Features:

Magnetic Flux Monitoring Ports: Real-time strength verification without disassembly

FDA/EU1935 Compliance: Full documentation for food contact applications

Rapid-Change Kits: Convert standard units to ATEX-rated versions in 15 minutes

Self-cleaning Magnetic Drawer Filter

Self-cleaning magnetic drawer filter with a scraperboard is the ideal solution for removing ferrous metals from plastic granules and easily cleaning the ferrous from magnetic bars with a special scraper design made of PEEK polymer for zero metal-to-metal contact, and room working temperature (operational range: -40°C to 120°C).

Magnetic strength is as follows:

8000GS - Standard food processing

10000GS - Heavy-duty metal recovery

12000GS - Pharmaceutical-grade purification

Pro Tip: Pair with our Magnetic Trap Efficiency Calculator to determine optimal Gauss rating for your material density and flow rate.

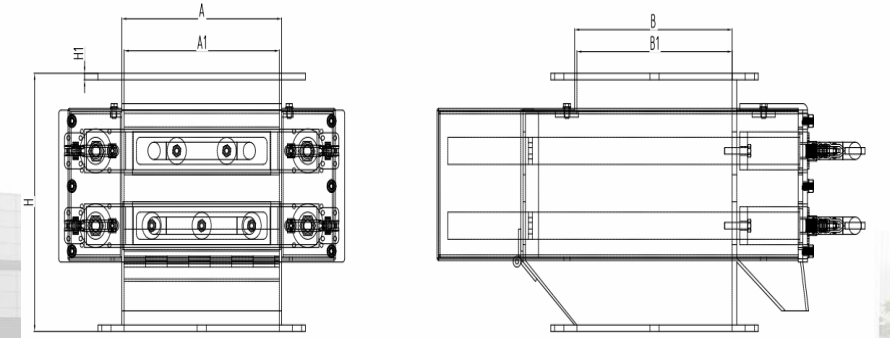

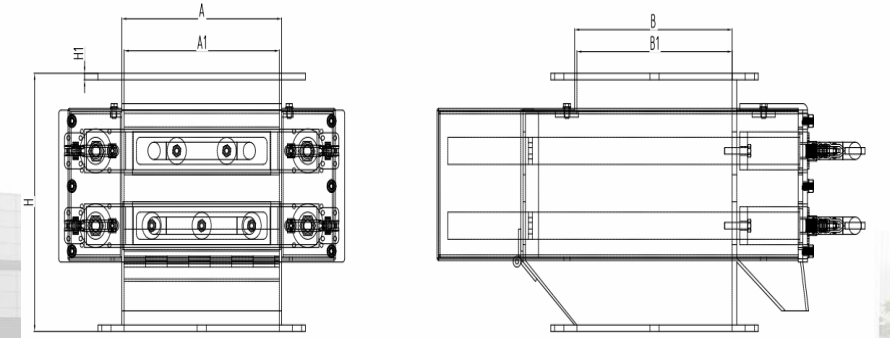

| Model No. | Dimension(mm) | Bar Qty | Weight(KG) |

| A | A1 | B | B1 | H | H1 |

| MD20×20SF-IG | 208 | 202 | 205 | 202 | 238 | 6 | 2+3 |

|

| MD25×25SF-IG | 258 | 252 | 255 | 252 | 238 | 6 | 3+4 |

|

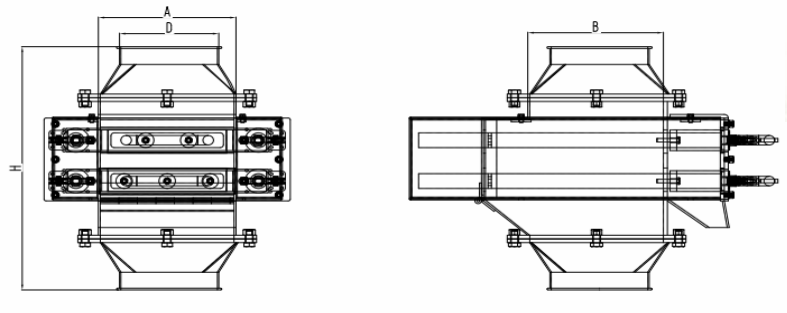

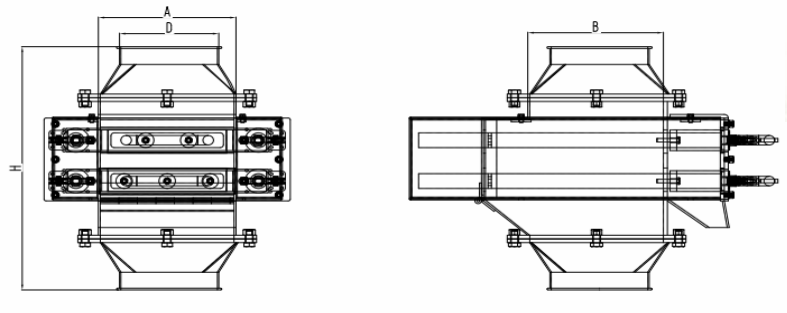

| Model No. | Dimension(mm) | Bar Qty | Weight(KG) |

| A | B | H | D |

| MD150RF-IG | 208 | 205 | 444 | 150 | 2+3 |

|

| MD200RF-IG | 258 | 255 | 444 | 200 | 3+4 |

|

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية