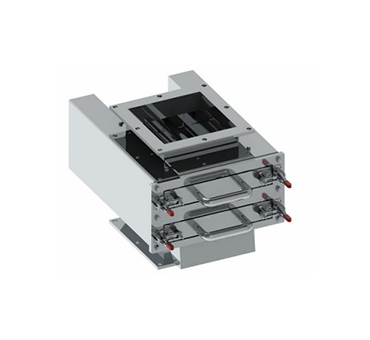

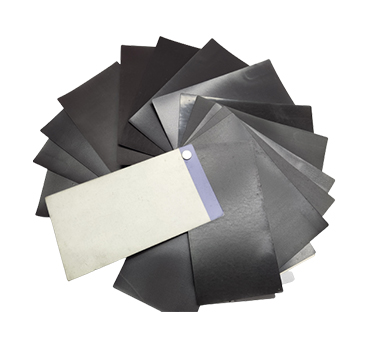

Many different styles are available for different materials.

The max magnetic strength can reach 14,000GS for N-style and 10,000GS for E-style.

Standard working temperature ≤ 80℃, max working temperature can be chosen from 80℃ to 350℃ as the same with magnetic bars if needed.

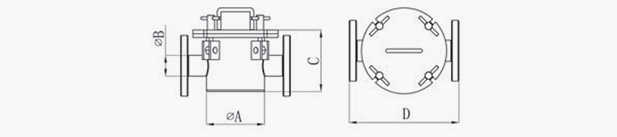

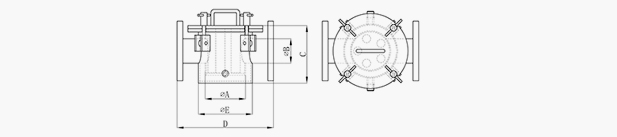

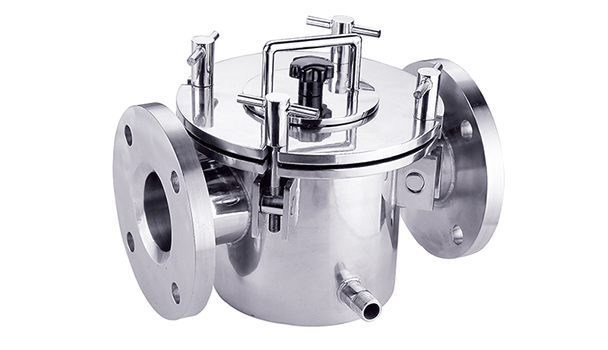

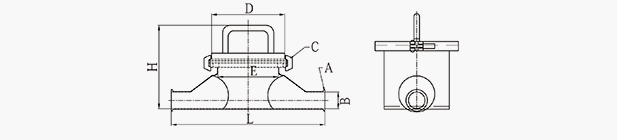

The connection can be through a ferrule, bolt plate, flange, or uneven head.

Stainless steel 304 or 316L is available for shell material.

The property-designed magnetic configuration ensures maximum magnetic effect without impeding liquid flow.

Pressure design or other special requirements can be custom-made.

How do Souwest Magnetech Magnetic Traps work?

Magnetic traps, also known as magnetic filters or magnetic separators, are devices used to capture and remove ferrous (iron-based) and paramagnetic particles from various substances, such as liquids, gases, or bulk materials. These magnetic traps work based on the principles of magnetism to attract and retain magnetic particles, allowing the clean substance to pass through without any magnetic impurities.

The basic working principle of magnetic traps involves the following steps:

Magnetic Field Generation: Magnetic traps contain strong permanent magnets or electromagnets that generate a magnetic field within their vicinity. The magnetic field lines extend from the magnets and create a region of magnetic influence.

Particle Attraction: When a substance containing ferrous or paramagnetic particles passes through the magnetic trap, these magnetic particles are drawn towards the strong magnetic field lines. The magnetic force overcomes the gravitational or flow forces acting on the particles, causing them to be captured and held onto the trap's surface.

Particle Retention: The captured magnetic particles adhere to the surface of the magnetic trap, staying in place even when the substance continues to flow. The trapped particles create a barrier that prevents other magnetic impurities from passing through.

Clean Substance Passage: As the clean substance flows through the magnetic trap, the non-magnetic materials continue their normal path, while the captured magnetic particles remain immobilized on the trap's surface.

Cleaning and Maintenance: Over time, the magnetic trap accumulates a buildup of trapped particles. Periodically, the trap needs to be cleaned or purged to remove the captured magnetic impurities, ensuring its continued effectiveness.

Magnetic traps find application in various industries, such as food processing, pharmaceuticals, chemical manufacturing, mining, and recycling, where removing magnetic impurities is essential to maintain product quality, prevent equipment damage, and ensure safety and regulatory compliance.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية