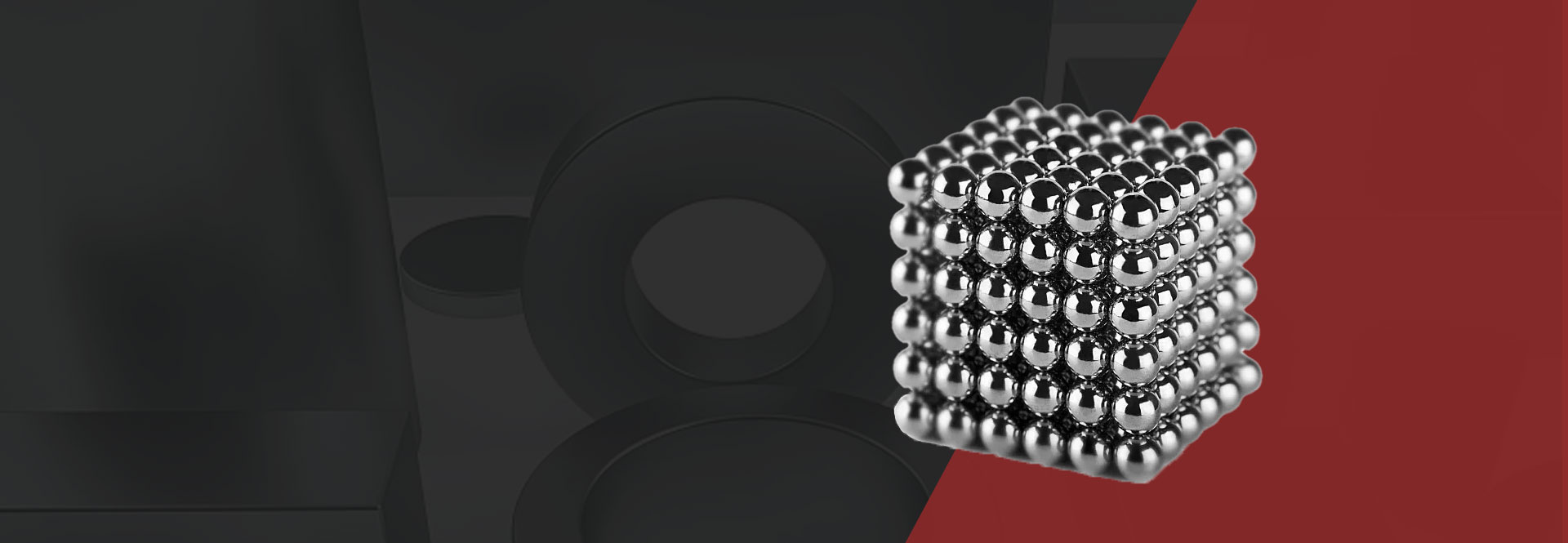

Technical Specifications

Parameter | Specification |

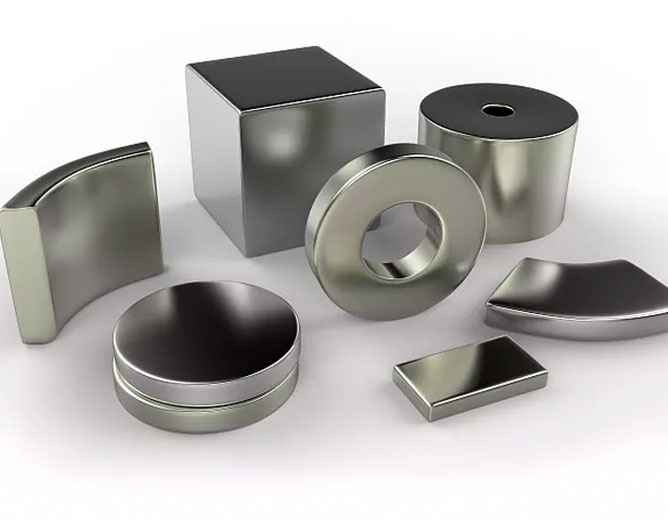

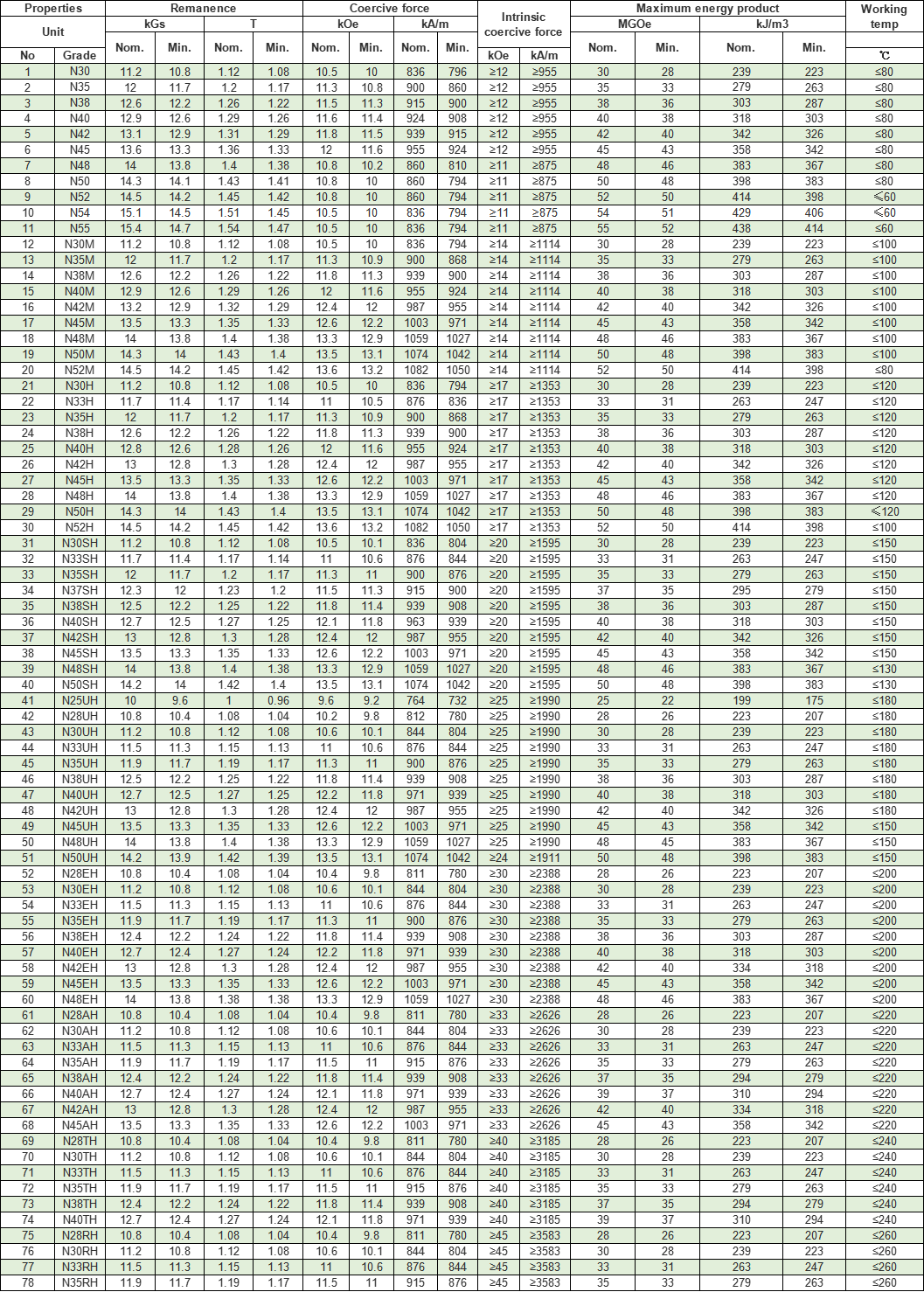

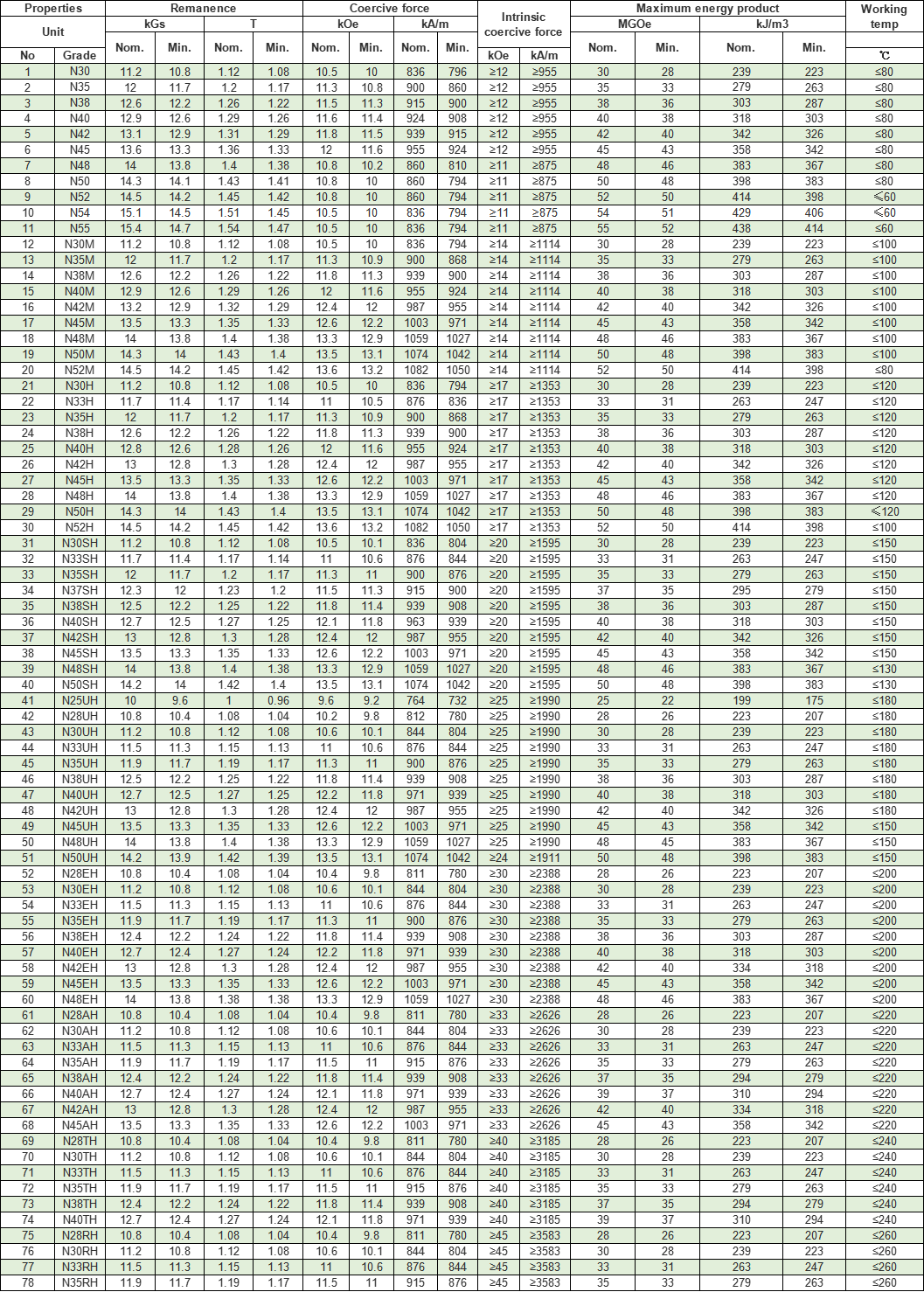

Material Grade | N35, N38, N42, N45, N50, N52 |

Max Energy Product | 52MGOe |

Coating Options | Ni-Cu-Ni, Epoxy, Gold, Zinc |

Pull Force Range | 1.5kg to 280kg (tested per ASTM A977) |

Tolerance | ±0.05mm precision |

Industrial Applications of Bulk Neo Magnets

1. Electric Motors & Generators: High-torque N50SH magnets for EV drivetrains and wind turbines.

2. Medical Imaging: Ultra-stable NdFeB blocks for MRI machines (low magnetic decay <0.5%/year).

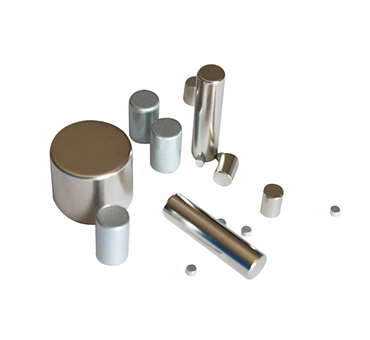

3. Robotics & Automation: Miniature disc magnets (3mm-10mm) for grippers and sensors.

4. Renewable Energy: Custom arc magnets for wind turbine pitch control systems.

5. Case Study: A German auto supplier reduced motor assembly costs by 22% using our custom rectangular neo magnets with chamfered edges for seamless integration.

Customization Services

· Prototyping: 3D-printed magnet samples within 72 hours.

· Specialized Coatings: FDA-approved epoxy for food processing equipment.

· Magnetizing Patterns: Radial, multi-pole, or axial orientations.

Neodymium vs Ferrite Magnets: Key Differences

Feature | Neodymium Magnets | Ferrite Magnets |

Magnetic Strength | 10-15x stronger | Standard |

Temperature Range | -50°C to +260°C | -40°C to +250°C |

Corrosion Resistance | Requires coating | Naturally resistant |

Cost Efficiency | Higher performance/price | Lower upfront cost |

Safety & Handling Guidelines

⚠️ Critical Precautions for Wholesale Neo Magnets:

· Use non-conductive tools to prevent accidental snapping (force up to 280kg).

· Store in anti-static packaging ≥50cm from pacemakers/electronics.

· For bulk orders, request our magnetic shielding pallets to prevent transit damage.

Order with Confidence

✉️ Contact our NdFeB specialists today for:

· Instant neodymium magnets bulk pricing (volume discounts applied automatically).

· Free magnetic flux analysis reports.

· EXW/FOB/CIF logistics solutions from our Shenzhen facility.

【Request Free Sample Kit】 Test N35-N52 grades side-by-side with your application!

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية