The process of rubber magnets

Rubber magnets are a type of synthetic magnet. Magnetic powder (mainly ferrite powder, sometimes neodymium iron boron powder) is mixed with nitrile plastic and then extruded. We also provide magnetization services for customers. The production process includes: raw material preparation; mixing in proportion ; equipment stirring and extrusion molding; trimming and processing into rolls; cutting according to customer needs; packaging and transportation. Rubber magnet processing technology: adding magnetic chemical substances during the production of rubber, which makes the rubber magnetic after vulcanization. This is magnetic rubber. Almost all rubber can be made into magnetic rubber. Before molding, it can be made into any shape according to the vulcanization. Because rubber is very soft, it can be rolled up and used as a magnetic seal, etc.

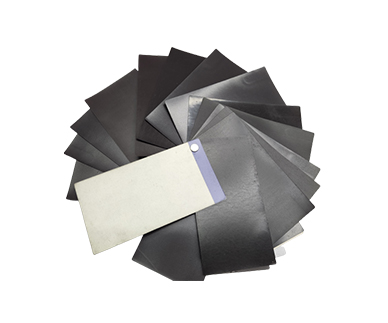

Rubber magnets with good performance

Rubber magnets for sale are flexible, flexible, and aging-resistant. They can be produced in various shapes according to customer needs, such as rolls, sheets, strips, and rings, through processes such as equipment extrusion and molding. Rubber magnets are magnets that are made by bonding ferrite magnetic powder, synthetic rubber, and other materials. They are flexible, elastic, and twistable. Because they can be produced in various shapes such as strips, rolls, sheets, and various complex shapes, rubber magnets are widely used in industries such as micro motors, refrigerators, disinfection cabinets, wardrobes, toys, stationery, and advertising. Rubber magnets have good performance, low cost, simple production process, and save a lot of expensive metals. They are non-metallic magnetic materials with development prospects in the field of high-frequency weak electricity.

Applications of rubber magnets

Consumer electronics

In daily life, various magnetic sensors, switches, motor magnetic materials, adsorbent magnetic products and components in household appliances are playing a huge role, significantly improving the quality of life.

Automotive electronics

All kinds of rubber magnets, adsorption, and motor rotor components are needed from the electrical system of new energy vehicles to electronic products in the interior of automobiles.

Computers and peripherals

The motor rotor in the computer optical storage device, the magnetic steel mechanical parts and storage components in the magnetic storage device, non-contact sensing and switch devices, and magnetic toner in various printing and copying equipment are all the use of high-performance rubber magnets.

Advertising, gifts, and educational supplies

In various advertising and promotional materials, the application of custom rubber magnets and adsorbent magnetic materials and components is extensive. In toys and educational supplies, various high-performance magnetic materials and components that meet environmental health standards are also playing an important role.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية