When it comes to high-temperature applications, choosing between Alnico and SmCo rare earth magnets can be a crucial decision for your project's success. While both magnets excel in elevated temperature environments, they possess distinct characteristics that set them apart. Alnico magnets can withstand temperatures up to 600°C, making them ideal for extreme heat conditions, while some grade SmCo magnets operate efficiently up to 550°C with superior magnetic strength. Are you wondering which magnet type would best suit your high-temperature application? Whether you're working in aerospace, automotive, or industrial sectors, understanding these differences is essential for optimal performance. In this comprehensive guide, we'll explore 7 key differences between AlNiCo and SmCo magnets, covering everything from temperature resistance to cost-effectiveness. Let's dive into the specifics and help you make an informed decision for your high-temperature applications. Explore our SmCo magnet products for extreme environments → or Alnico magnets

AlNiCo Magnets SmCo magnets

Key Takeaways:

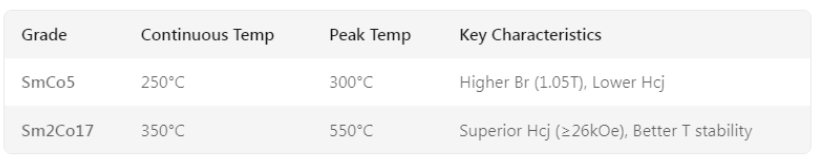

Alnico magnets offer exceptional temperature resistance up to 600°C, making them ideal for extreme temperature environments, while Some Grades SmCo magnets operate effectively up to 550°C, Some Grades are only to 350°C.

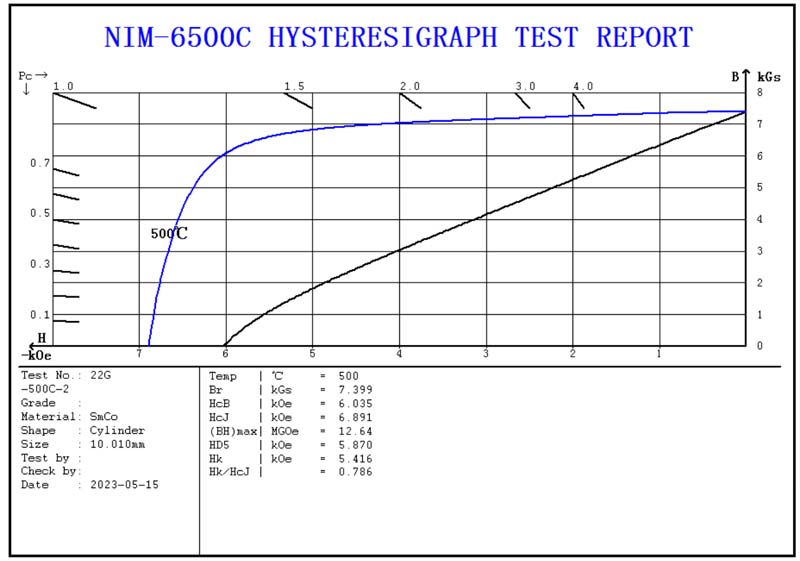

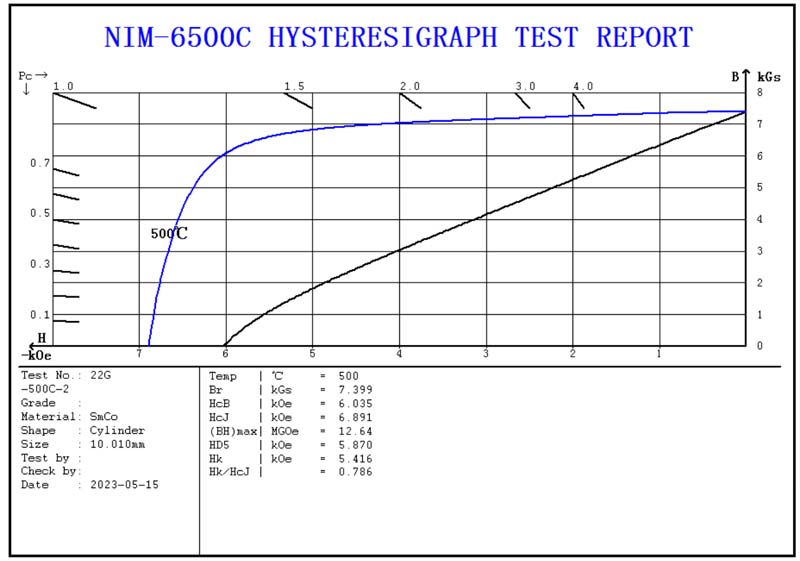

Demag Curve of SmCo magnets on 500°C

SmCo magnets provide superior magnetic strength and stability, offering stronger magnetic fields compared to Alnico, despite their lower temperature threshold.

Both magnet types demonstrate excellent corrosion resistance, with SmCo rare earth magnets having a slight edge in harsh environmental conditions.

While Alnico magnets are more cost-effective, SmCo magnets justify their higher price through superior magnetic properties and performance in technical applications.

The manufacturing process and material composition significantly influence each magnet's unique properties, with SmCo being part of the rare-earth magnet family and AlNiCo being an alloy-based magnet.

Understanding Alnico and SmCo Magnets

Alnico Magnets

Alnico magnets are permanent magnets composed of aluminum, nickel, and cobalt. These magnets are renowned for their exceptional thermal stability and ability to maintain magnetic properties at high temperatures up to 450-600°C. Their unique composition allows them to operate reliably in demanding environments without significant loss of magnetic strength.

SmCo Magnets

Samarium Cobalt (SmCo) magnets represent a class of rare-earth magnets that combine superior magnetic properties with excellent temperature resistance. These magnets can withstand temperatures up to 550°C while maintaining their magnetic characteristics. They offer high coercivity and strong resistance to demagnetization, making them ideal for precision applications.

Core Composition

Alnico magnets typically contain approximately 10% aluminum, 17% nickel, 12.5% cobalt, 6% copper, and 54.5% iron. This specific composition results in their distinctive magnetic properties. SmCo magnets, on the other hand, are made from samarium, cobalt, and small amounts of other rare earth elements, creating a highly stable magnetic material.

Manufacturing Process

Both magnet types undergo different manufacturing processes. Alnico magnets are produced through casting or sintering, followed by heat treatment to achieve optimal magnetic properties. SmCo magnets are manufactured using powder metallurgy techniques, involving pressing and sintering of fine powders under controlled conditions to create dense, highly magnetic materials.

Temperature Performance and Stability

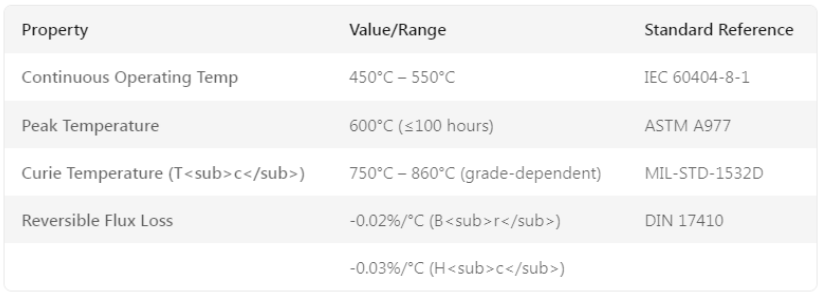

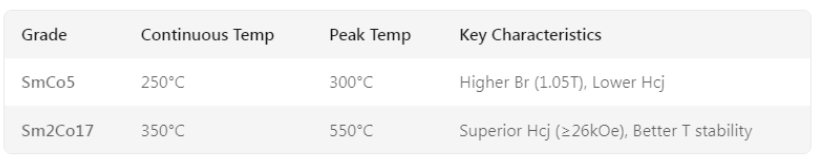

SmCo magnets core temperature parameters

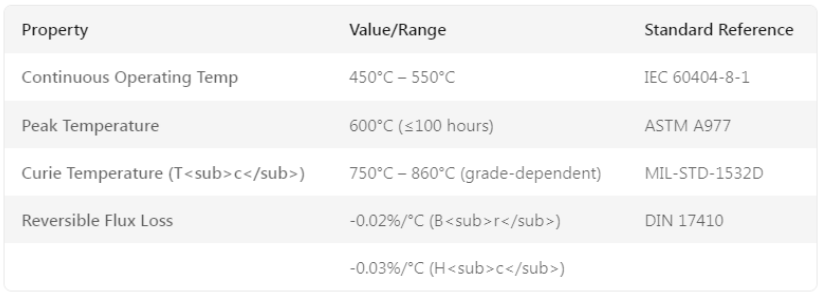

AlNiCo Magnets core temperature parameters.

Maximum Operating Temperature

SmCo magnets demonstrate exceptional stability at elevated temperatures, maintaining their magnetic properties up to 550°C. This remarkable temperature resistance makes them ideal for demanding applications where consistent performance is crucial. Their unique crystal structure and composition contribute to minimal magnetic flux losses even under prolonged heat exposure.

In contrast, AlNiCo magnets showcase superior temperature performance, capable of operating efficiently at temperatures reaching 600°C. This outstanding heat resistance stems from their aluminum-nickel-cobalt composition, which provides excellent thermal stability. They exhibit minimal irreversible losses when exposed to high temperatures, making them particularly valuable in extreme thermal environments.

Thermal Stability and Reversible Losses

When it comes to thermal stability, both magnet types display distinct characteristics. SmCo magnets feature a reversible temperature coefficient of -0.035%/°C, indicating slight temporary magnetic strength variations with temperature changes. Once the temperature returns to normal, these magnets quickly recover their original magnetic properties.

Alnico magnets possess an exceptionally low reversible temperature coefficient of -0.02%/°C, resulting in minimal magnetic strength fluctuations during temperature variations. This characteristic ensures consistent performance across a wide temperature range, though they may require careful handling to prevent demagnetization from strong external magnetic fields.

Both materials demonstrate different behaviors regarding long-term exposure to heat. SmCo magnets maintain their magnetic properties with minimal degradation over time, even when continuously operated at their maximum temperature. AlNiCo magnets exhibit remarkable stability at high temperatures, showing negligible aging effects and maintaining their magnetic strength even after extended periods at elevated temperatures.

Key Takeaway: SmCo magnets excel at temperatures up to 550°C with excellent stability, while AlNiCo magnets offer superior performance up to 600°C with minimal reversible losses, making them ideal for extreme temperature applications.

Magnetic Strength Comparison

Remanence and Coercivity

AlNiCo magnets exhibit a remanence (Br) of approximately 0.7-0.75 Tesla, while SmCo magnets demonstrate higher values ranging from 0.85-1.15 Tesla. This indicates that SmCo magnets can maintain stronger magnetic fields under normal conditions.

In terms of coercivity (Hc), SmCo magnets significantly outperform AlNiCo. SmCo magnets have coercivity values between 600-820 kA/m, while AlNiCo magnets only reach 40-60 kA/m. This means SmCo magnets are more resistant to demagnetization from external magnetic fields.

Maximum Energy Product

The maximum energy product (BHmax) is a crucial indicator of overall magnetic strength. SmCo magnets demonstrate superior performance with values ranging from 150-250 kJ/m³. AlNiCo magnets, however, have lower values around 40-50 kJ/m³, making them less powerful in terms of magnetic energy density.

Temperature Impact on Strength

At elevated temperatures, both magnets show different strength retention patterns. Alnico maintains its magnetic properties better at extreme temperatures (up to 600°C), experiencing only minimal strength loss. SmCo magnets, while having higher initial strength, start showing noticeable degradation above 350°C.

Stability Considerations

SmCo magnets offer excellent stability in their magnetic strength over time, with minimal aging effects. AlNiCo magnets, despite their lower initial strength, maintain consistent performance throughout their lifetime, particularly in high-temperature environments where stability is crucial.

Corrosion and Environmental Resistance

Chemical Resistance Properties

SmCo magnets demonstrate exceptional resistance to corrosion and oxidation, making them ideal for harsh environments. They maintain their magnetic properties even when exposed to various chemicals and atmospheric conditions. However, they may require additional protective coatings in extremely corrosive settings.

In contrast, AlNiCo magnets show moderate resistance to corrosion. While they can withstand some environmental factors, they are more susceptible to oxidation and may need protective treatments for long-term durability.

Environmental Stability

SmCo magnets excel in maintaining stability across diverse environmental conditions. They perform consistently in both humid and dry atmospheres, showing minimal degradation over time. Their robust nature makes them suitable for outdoor applications where weather exposure is inevitable.

AlNiCo magnets, while durable, may experience slight surface oxidation when exposed to moisture or aggressive environments. However, their core magnetic properties remain largely unaffected, ensuring reliable performance in most industrial settings.

Protective Measures

Both magnet types benefit from protective coatings:

- SmCo typically uses nickel plating or epoxy coating

- AlNiCo often requires zinc or nickel-copper-nickel coating

- Both can utilize specialized sealants for extreme conditions

These protective layers enhance longevity and maintain optimal performance in challenging environments without compromising magnetic properties.

Cost and Economic Considerations

Price Comparison

SmCo magnets typically command higher prices due to their complex manufacturing process and the use of rare earth elements. The cost can be 2-3 times higher than AlNiCo magnets, making them a significant investment for high-temperature applications.

Long-term Value Analysis

While Alnico magnets have a lower initial cost, their excellent temperature stability and longevity often provide better value over time. They require minimal maintenance and can operate efficiently at temperatures up to 600°C without degradation, reducing replacement costs.

Market Factors

Raw material availability plays a crucial role in pricing. SmCo magnets face price volatility due to rare earth element supply chain uncertainties. In contrast, Alnico magnets use more readily available materials, leading to more stable pricing.

ROI Considerations

When evaluating return on investment, consider application-specific factors:

- Operating temperature requirements

- Expected service life

- Maintenance costs

- Performance stability needs

- Production volume requirements

Industrial and Technical Applications

High-Temperature Industrial Applications

In demanding industrial environments, both AlNiCo and SmCo magnets serve distinct roles based on their unique properties. AlNiCo magnets excel in extreme temperature settings, making them ideal for industrial furnaces and high-temperature sensing equipment operating at up to 600°C. Their exceptional thermal stability ensures consistent performance in hot industrial processes.

SmCo magnets, while limited to 350-550°C, offer superior magnetic strength and stability in moderately high-temperature applications. They are extensively used in High-temperature industrial motors, generators, and sensors where precise magnetic field control is crucial. Their resistance to demagnetization makes them particularly valuable in manufacturing automation systems.

Specialized Technical Uses

The technical applications of these magnets extend beyond traditional industrial settings. AlNiCo magnets find extensive use in scientific instruments and measurement devices that require stable magnetic fields at elevated temperatures. Their low temperature coefficient makes them reliable choices for calibration equipment and research apparatus.

SmCo magnets, with their higher magnetic strength, are preferred in precision instruments and advanced technical equipment. They are commonly found in high-end measuring devices, magnetic separation systems, and specialized sensors where maintaining strong magnetic properties under moderate temperature stress is essential.

These magnets also play crucial roles in power generation equipment. While AlNiCo magnets are used in high-temperature zones of turbines, SmCo magnets are typically employed in generator components where maximum magnetic strength is required under moderate temperature conditions.

Selection Criteria for High-Temperature Applications

Temperature Requirements

When selecting magnets for high-temperature applications, the first consideration is the maximum operating temperature. AlNiCo magnets can operate efficiently up to 600°C, while SmCo magnets typically work best up to 350-550°C. It's crucial to factor in both continuous and intermittent temperature exposure.

Magnetic Stability

The magnetic stability at elevated temperatures plays a vital role in selection. SmCo magnets maintain their magnetic properties better at high temperatures, showing minimal flux loss. Alnico, while capable of handling higher temperatures, may experience some reversible magnetic changes.

Application Environment

Consider the overall operating environment beyond just temperature. SmCo5 magnets offer superior corrosion resistance and require no additional coating for most applications because there is no iron in SmCo 5 magnet series. Sm2CO17 magnets and AlNiCo magnets might need protective coatings in corrosive environments, despite their excellent temperature resistance.

Cost Considerations

Budget constraints often influence the final choice. SmCo magnets typically come at a higher price point but offer better stability and performance. Alnico magnets, while more economical, might require additional protective measures, impacting the total cost.

Key Takeaway: Choose between Alnico and SmCo based on maximum operating temperature, magnetic stability requirements, environmental conditions, and budget constraints while considering the specific demands of your application.

Conclusion

Understanding the key differences between Alnico and SmCo magnets is crucial for making informed decisions in high-temperature applications. While AlNiCo magnets offer exceptional temperature resistance up to 600°C and better stability, SmCo5 magnets provide superior magnetic strength and corrosion resistance at temperatures up to 350°C. Each magnet type brings unique advantages to specific applications. AlNiCo's excellent temperature stability makes it ideal for extreme environments, while SmCo's powerful magnetic field strength suits applications requiring compact, high-performance solutions. Consider your specific requirements, including operating temperature, space constraints, and budget, when choosing between these magnetic materials. Whether you're designing for aerospace, automotive, or industrial applications, selecting the right magnet type can significantly impact your project's success. Take time to evaluate these differences carefully, and consult with magnet manufacturers to ensure optimal performance in your high-temperature applications.

FAQs

What is the cost difference between Alnico and SmCo magnets?

SmCo magnets are generally more expensive than Alnico magnets due to their rare earth composition and complex manufacturing process. However, their superior performance in high-temperature environments often justifies the higher investment for critical industrial applications.

How long do Alnico and SmCo magnets typically last in high-temperature applications?

Both magnet types offer excellent longevity when properly used. SmCo magnets can maintain their magnetic properties for 10-20 years in high-temperature environments, while Alnico magnets may experience slight degradation over time but can still function effectively for many years with proper care.

Can these magnets be customized for specific industrial applications?

Yes, both Alnico and SmCo magnets can be customized in terms of shape, size, and coating options. SmCo offers more flexibility in customization due to its manufacturing process, while AlNiCo has some limitations due to its casting requirements.

Are there any special storage requirements for Alnico and SmCo magnets?

Both magnets should be stored in a cool, dry environment away from strong magnetic fields. SmCo magnets require additional care as they're more brittle and susceptible to chipping, while AlNiCo magnets are more robust and require less careful handling.

How do environmental factors affect the performance of these magnets?

SmCo magnets offer excellent corrosion resistance and maintain performance in humid conditions. Alnico magnets may require additional coating for corrosion protection but generally handle environmental stress well. Both perform reliably in high-temperature industrial environments.

What safety precautions should be taken when handling these magnets?

Both magnets require careful handling due to their strong magnetic fields. Use protective equipment and keep them away from electronic devices. SmCo magnets need extra care due to their brittleness, while Alnico magnets are more forgiving but still require proper safety protocols.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية