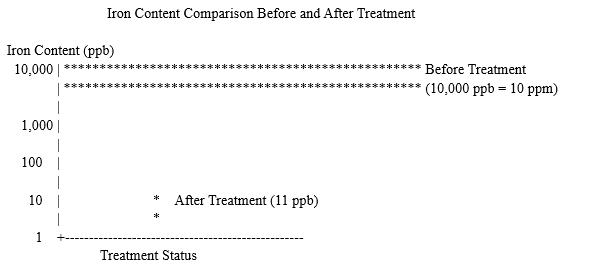

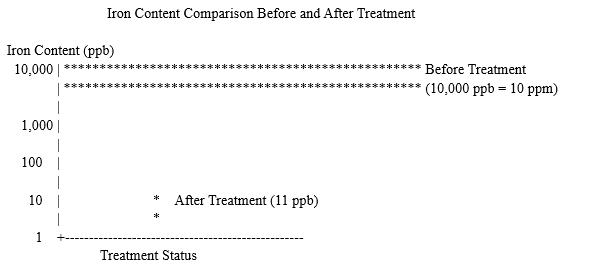

For lithium-ion battery manufacturers, controlling iron impurities in anode graphite is critical to maximizing energy density, cycle life, and safety. While the industry standard hovers around <10ppm,cutting-edge applications now demand sub-20ppb precision—a challenge traditional methods struggle to meet. Here’s how our advanced Nano Magnetic Filtration System delivers 11ppb iron content, setting a new benchmark for high-purity production.

☆Industry Challenges & Standards

· Current Standards: Most anode graphite materials require iron content below 10ppm(GB/T 24533-2019). However, high-performance batteries (e.g.,solid-state, silicon-carbon anodes) demand <20ppb to minimize self-discharge and capacity fade.

· Traditional Limitations: Conventional filtration often fails to capture micron/nano-scale iron particles,leading to inconsistent results and yield losses.

☆ Our Solution: Nano Magnetic Filtration Technology

✅ Multi-Layer Gradient Magnetic Capture:

· Targets 0.1–10µm iron impurities with >90% efficiency, surpassing standard magnetic filters.

· Zero material loss: Proprietary separation ensures high-purity graphite retention.

✅ SmartIntegration & Real-Time Monitoring:

· Modular design integrates into existing lines in <72 hours with minimal downtime.

· Live data dashboards track iron content, ensuring ppm-to-ppb consistency.

☆ Proven Results

Iron Reduction: From 10ppm to 11ppb (99.89% removal).

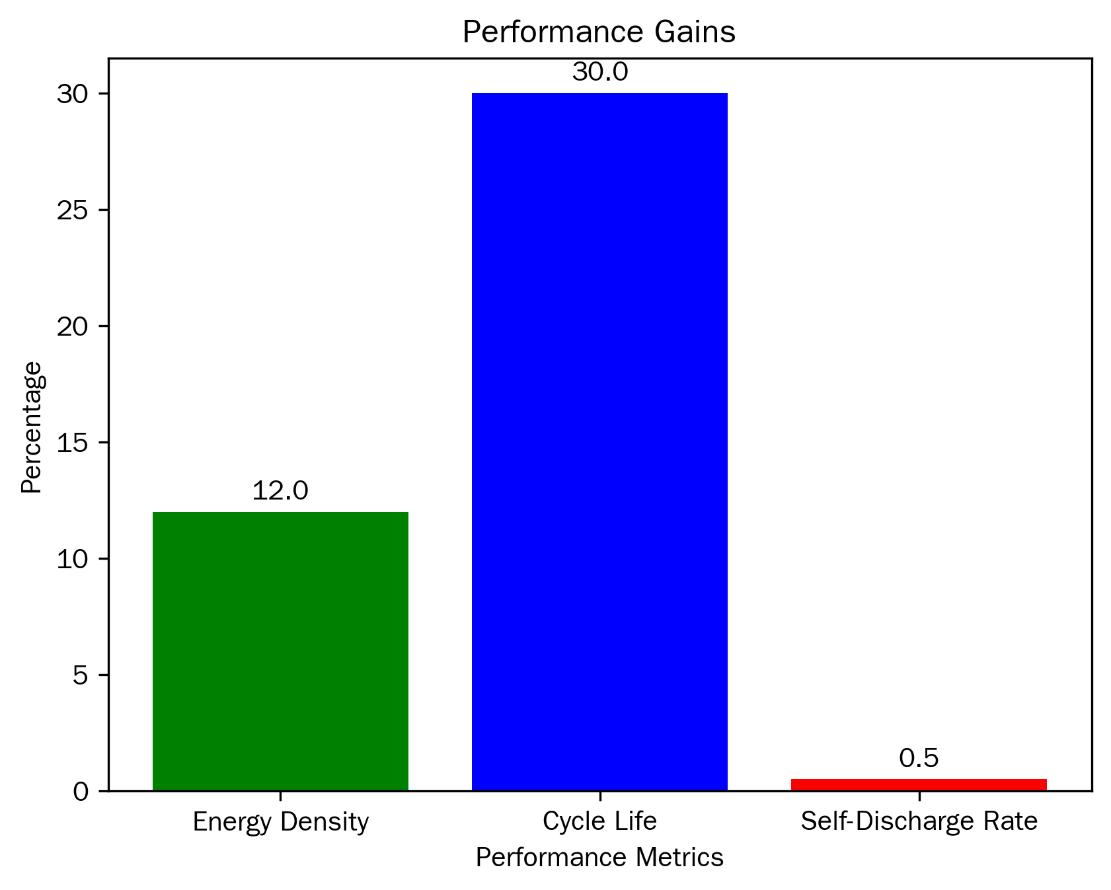

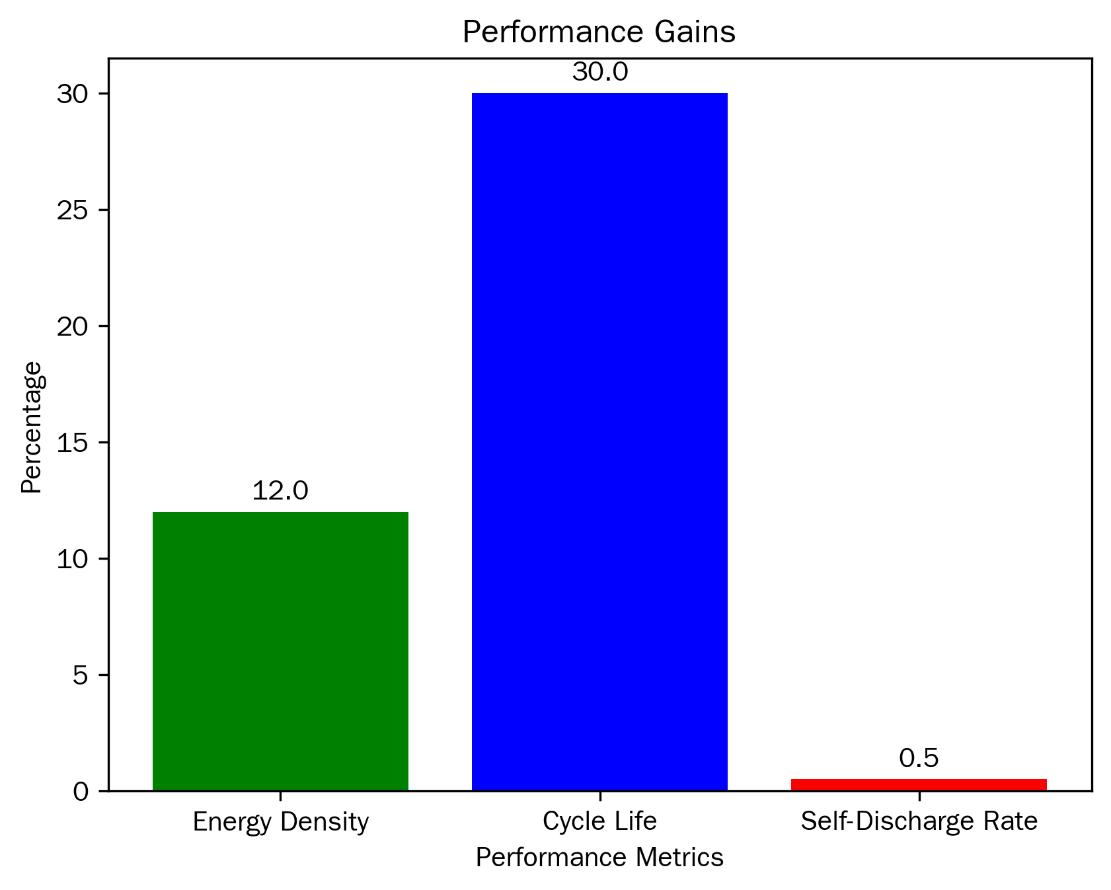

· Performance Gains:

§ +12% Energy Density

§ +30% Cycle Life

§ Self-Discharge Rate ↓ to 0.5%/month

· Client Testimonial:“This system is the only solution that meets our automotive-grade specs for next-gen EV batteries.” – Top-tier battery supplier.

☆ Who Benefits?

· Battery Manufacturers: Developing high-nickel/SiC anodes or solid-state batteries.

· Material Suppliers: Battling sub-95% yield due to iron contamination.

· R&D Teams: Innovating in sodium-ion or ultra-fast-charging technologies.

☆ Contact Us Today:

☆ www.magnetsw.com

☆ Email: sales@magnetsw.com

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية