Looking to purchase neodymium magnets in bulk but worried about getting the best value for your investment? Wholesale neodymium magnets can offer significant cost savings, but navigating the purchasing process requires careful consideration of quality, safety, and pricing factors. As the strongest permanent magnets available, these powerful tools demand both expertise and caution in procurement. In this comprehensive guide, we'll walk you through everything you need to know about wholesale neodymium magnets, from understanding grades and coatings to implementing safe handling practices.

Whether you're a business owner seeking industrial magnets or a project manager looking to optimize costs, we'll help you:

Identify the most cost-effective bulk ordering strategies

Select the right magnet specifications for your needs

Navigate supplier relationships for better pricing

Implement essential safety protocols Let's dive into the world of wholesale neodymium magnets and discover how to maximize your savings while ensuring quality and safety.

Key Takeaways:

Neodymium magnets, being the strongest permanent magnets available, offer significant cost savings when purchased in bulk for industrial applications and various other uses.

Quality considerations include magnet grade, coating options (such as nickel-copper-nickel layer), and magnetic properties that match your specific requirements.

Bulk ordering strategies can help you achieve unbeatable savings through seasonal discounts, limited-time sales, and strategic relationships with magnet wholesalers.

Safety is paramount when handling these powerful magnets - proper protocols must be established for storage, handling, and maintaining safe distances from sensitive equipment and fragile items.

Working with reliable magnetic solution providers ensures you get the highest quality magnets while benefiting from wholesale pricing and expert guidance.

Understanding Neodymium Magnets and Their Properties

Neodymium magnets, also known as NdFeB magnets, are the strongest permanent magnets available today. These rare-earth magnets are made from an alloy of neodymium, iron, and boron, creating a powerful magnetic force that's essential for various industrial and commercial applications.

Composition and Structure

The unique composition of neodymium magnets gives them their exceptional magnetic properties. The primary elements include approximately 31% neodymium, 65% iron, and 1% boron, along with small amounts of other elements. This specific combination results in a tetragonal crystalline structure that produces intense magnetic fields.

The manufacturing process involves powder metallurgy techniques where the raw materials are melted, formed into powder, and then compressed and sintered to create the final magnet. This process aligns the magnetic domains to maximize the magnetic strength.

Magnetic Properties and Grades

Neodymium magnets are classified by their maximum energy product, measured in MGOe (Mega Gauss Oersteds). The grade system starts with the letter "N" followed by a number - typically ranging from N35 to N52. Higher numbers indicate stronger magnetic force.

These magnets exhibit impressive magnetic properties:

High coercivity (resistance to demagnetization)

Strong remanence (residual magnetism)

Maximum energy product up to 54 MGOe

Operating temperatures up to 80°C for standard grades

The strength of these magnets makes them ideal for applications requiring powerful magnetic fields in compact spaces. However, their strong magnetic force also means they require careful handling to prevent accidents and damage to sensitive equipment.

Key Takeaway: Neodymium magnets are powerful permanent magnets composed of rare-earth elements, featuring a unique crystalline structure and grading system that makes them ideal for various industrial applications requiring strong magnetic fields.

Benefits of Wholesale Purchasing

Cost Savings Through Bulk Orders

When you purchase neodymium magnets in wholesale quantities, you can significantly reduce your per-unit costs. Manufacturers and suppliers often provide substantial discounts on large orders, helping you maximize your budget. These savings can range from 20% to 50% compared to retail prices, making it an economically smart choice for businesses and regular users alike.

Consistent Quality and Supply

Wholesale purchasing ensures you receive magnets from the same production batch, guaranteeing uniform quality and performance across your order. This consistency is crucial for manufacturing processes and product development. Additionally, maintaining a steady supply helps prevent production delays and ensures you always have magnets available when needed.

Establishing a relationship with a wholesale supplier also gives you priority access to new products, special offers, and technical support. You'll benefit from their expertise in magnet selection and application, helping you make informed decisions for your specific needs.

By buying in bulk, you can also reduce packaging waste and transportation costs, making it an environmentally conscious choice. Many wholesale suppliers offer customized packaging solutions that better suit your storage and handling requirements.

Key Takeaway: Wholesale purchasing of neodymium magnets offers significant cost savings, ensures consistent quality, and provides reliable supply chain benefits while reducing environmental impact through bulk packaging.

Common Industrial Applications

Manufacturing and Assembly

Neodymium magnets play a vital role in modern manufacturing processes. These powerful magnets are extensively used in automated assembly lines for part handling, positioning, and temporary holding during production. Their exceptional strength makes them perfect for magnetic conveyor systems and robotic pick-and-place operations.

In automotive manufacturing, neodymium magnets are used to hold metal components securely during welding and assembly. They're also integrated into magnetic workholding fixtures, providing a quick and efficient way to secure parts during machining operations.

Material Handling and Lifting

The remarkable strength-to-size ratio of neodymium magnets makes them indispensable in material handling applications. Industrial lifting magnets equipped with neodymium cores can safely lift and transport heavy metal objects, significantly improving workplace efficiency and safety.

These magnets are commonly found in:

Magnetic sweepers for collecting metal debris

Lifting systems for steel plates and pipes

Magnetic separators in recycling facilities

Automated sorting systems

Magnetic grippers in robotic applications

The lifting capacity of industrial-grade neodymium magnets can range from a few pounds to several tons, depending on their size and grade. When properly coated with nickel or zinc, they offer excellent corrosion resistance, making them suitable for both indoor and outdoor applications.

In the recycling industry, powerful magnetic separators using neodymium magnets help sort ferrous materials from mixed waste streams. This application has become increasingly important as industries focus on sustainable practices and efficient resource recovery.

Many modern warehouses and distribution centers utilize magnetic solutions for inventory management and material handling. Magnetic rack labels, holding fixtures, and temporary mounting solutions all rely on the superior strength of neodymium magnets to maintain organization and improve operational efficiency.

Key Takeaway: Neodymium magnets are essential in industrial settings, from manufacturing assembly lines to heavy-duty lifting operations, offering reliable solutions for automated processes and material handling challenges.

Selecting the Right Neodymium Magnets

Understanding Magnet Grades

When selecting neodymium magnets for your bulk purchase, understanding magnet grades is crucial. The N-rating system, ranging from N35 to N52, indicates the magnetic strength. Higher numbers represent stronger magnetic force, with N52 being the most powerful grade currently available.

The grade you choose depends on your specific application. For general industrial use, N42 magnets offer a good balance of strength and cost-effectiveness. If you need maximum magnetic force, N52 magnets are your best bet, though they come at a premium price point.

Choosing the Right Shape and Size

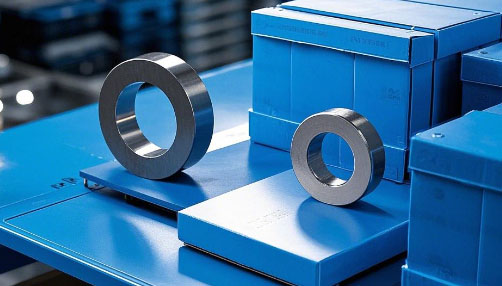

The shape and size of your neodymium magnets significantly impact their performance. Common shapes include discs, blocks, rings, and cylinders. Each shape serves different purposes:

Disc magnets work well for mounting and holding applications

Block magnets excel in linear motion systems

Ring magnets are perfect for sensors and motors

Cylinder magnets suit rotary applications

Size selection requires careful consideration of your space constraints and required magnetic force. Remember that larger magnets generally provide stronger magnetic fields, but they also cost more and may be harder to handle safely.

Consider these factors when determining dimensions:

Always factor in a safety margin when selecting sizes, as magnetic force can decrease over time or with exposure to high temperatures. For optimal performance, choose dimensions that slightly exceed your minimum requirements.

Key Takeaway: Select neodymium magnets based on their grade (N35-N52) and shape (disc, block, ring, cylinder), while considering your specific application needs, space constraints, and safety requirements for optimal performance.

Storage and Handling Guidelines

Safe Storage Practices

Proper storage of neodymium magnets is crucial to maintain their strength and prevent accidents. Keep them in their original packaging or a sturdy, non-magnetic container. Store them in a cool, dry place away from direct sunlight and heat sources, as extreme temperatures can affect their magnetic properties.

Always separate strong magnets with non-magnetic dividers to prevent them from snapping together. Wood, plastic, or cardboard spacers work well for this purpose. For larger quantities, consider using storage cabinets with individual compartments to keep magnets organized and safely apart.

Handling Precautions

When handling neodymium magnets, safety should be your top priority. Wear protective gloves and safety glasses to guard against potential injuries from sudden magnetic attraction. Keep magnets at least 20 inches away from electronic devices and magnetic storage media to prevent data loss or damage.

Exercise extreme caution when working with multiple magnets. Their strong attractive force can cause them to snap together unexpectedly, potentially causing serious pinch injuries. Always maintain a firm grip and keep your fingers clear of the space between magnets.

For workplace settings, establish clear handling protocols and ensure all personnel are properly trained. Create designated work areas away from sensitive equipment and mark them clearly with warning signs. When moving large quantities, use non-magnetic tools and equipment to maintain control and prevent accidents.

Key Takeaway: Store neodymium magnets in cool, dry places with proper separation, and handle them with protective gear while maintaining safe distances from electronic devices and following established safety protocols.

Sourcing from Reliable Suppliers

Finding a trustworthy supplier for wholesale neodymium magnets is crucial for ensuring quality and reliability. When sourcing these powerful magnets, it's essential to work with established manufacturers or distributors who have a proven track record in the industry.

Quality Certifications

Look for suppliers who maintain ISO certifications and follow international quality standards. These certifications indicate their commitment to maintaining consistent product quality and manufacturing processes. Reputable suppliers should also provide detailed specifications and test reports for their products.

Pricing Transparency

A reliable supplier will offer clear pricing structures for bulk orders. They should be upfront about minimum order quantities, volume discounts, and any additional costs like shipping or customs fees. Be wary of suppliers offering prices significantly lower than market rates, as this could indicate inferior quality.

Customer Support

Choose suppliers who provide comprehensive technical support and readily answer your queries. They should be able to guide you through the selection process, helping you choose the right grade and coating for your specific application. Good suppliers also offer post-purchase support and handle any quality issues professionally.

Key Takeaway: Partner with certified suppliers who offer transparent pricing and excellent customer support to ensure reliable quality and service for your wholesale neodymium magnet purchases.

Special Applications and Solutions

Industrial Lifting Solutions

Neodymium magnets excel in heavy-duty industrial lifting applications. Their exceptional strength makes them perfect for handling steel plates, machinery parts, and construction materials. These magnets can significantly streamline material handling processes while reducing manual labor requirements.

Automotive and Manufacturing

In automotive manufacturing, neodymium magnets play a crucial role in assembly line operations. They're used in robotic arms, conveyor systems, and quality control equipment. Their precise magnetic fields ensure accurate positioning and movement of metal components during production.

Medical Equipment

The healthcare sector relies on neodymium magnets for various specialized applications. From MRI machines to surgical tools, these magnets provide the powerful magnetic fields needed for precise medical procedures and diagnostic imaging. Their reliability and consistent performance make them indispensable in medical technology.

Research and Development

Scientific research facilities utilize neodymium magnets in particle accelerators, magnetic separation systems, and experimental setups. Their strong magnetic properties enable researchers to conduct advanced experiments in physics, chemistry, and materials science.

Key Takeaway: Neodymium magnets serve diverse specialized applications across industries, from industrial lifting to medical equipment, offering powerful solutions for complex technical challenges.

Conclusion

As you embark on your wholesale neodymium magnet purchasing journey, remember that success lies in balancing cost-effectiveness with quality and safety. By following the guidelines outlined in this guide, you'll be well-equipped to make informed decisions that maximize your savings while ensuring optimal performance for your industrial applications. Whether you're sourcing magnets for water softener devices, electronic components, or magnetic closure systems, take advantage of bulk ordering discounts, seasonal promotions, and strategic supplier relationships. Don't forget to prioritize safety protocols and proper handling procedures to protect both your investment and your team. Ready to transform your magnet procurement strategy? Start implementing these cost-saving techniques today while maintaining the highest quality standards. Your success in the world of wholesale neodymium magnets awaits – begin your journey toward unbeatable savings and reliable magnetic solutions that will drive your business forward.

FAQs

What is the typical lifespan of neodymium magnets when used in industrial applications?

Neodymium magnets can last indefinitely when used properly in industrial settings. With proper coating (nickel-copper-nickel layer) and correct storage conditions, they maintain their magnetic properties for 20-30 years. However, exposure to extreme temperatures or harsh chemicals can reduce their lifespan.

How do I safely store bulk quantities of neodymium magnets?

Store neodymium magnets in a cool, dry place with controlled humidity. Keep them separated using non-magnetic dividers, and maintain safe distances between magnet stacks. For bulk storage, use wooden or plastic containers rather than metal ones to prevent unwanted magnetic interactions.

What certifications should I look for when purchasing wholesale neodymium magnets?

Look for magnets with RoHS certification (Restriction of Hazardous Substances), ISO 9001 quality management certification, and REACH compliance. These certifications ensure the magnets meet international safety and quality standards for industrial use and consumer products.

Can neodymium magnets lose their magnetization over time?

Under normal conditions and proper handling, neodymium magnets retain their magnetic properties indefinitely. However, exposure to temperatures above 176°F (80°C), strong opposing magnetic fields, or physical shock can cause demagnetization.

What's the minimum safe distance between strong neodymium magnets during transport?

Maintain at least 6-12 inches between large neodymium magnets during transport. Use non-magnetic spacers and proper packaging materials. For stronger grades (N52), increase this distance to prevent magnetic interference and ensure safe handling.

How do environmental factors affect neodymium magnet performance?

Temperature, humidity, and corrosive environments can significantly impact magnetic performance. Neodymium magnets perform best below 80°C (176°F) and in dry conditions. High humidity can cause corrosion unless the magnets have protective coatings.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية