What is Pot Magnet?

Pot magnets (also known as cup magnets) are highly versatile components used across industries—from automotive and manufacturing to retail and consumer applications. Their strong holding power, durable construction, and adaptability make them essential for mounting, clamping, and retrieval purposes.

This guide explores the leading global manufacturers of pot magnets, highlighting their specialties, production capabilities, and key differentiators to help businesses and consumers make informed purchasing decisions.

1. Souwest Magnetech – Innovation & Wholesale Excellence

Headquarters: China | Website: www.magnetsw.com

Company Overview

Since 2003, Souwest Magnetech has established itself as a premier manufacturer and wholesale supplier of pot magnets. With a 28,000 m² production facility, advanced R&D capabilities, and a stock management system ensuring 48-hour delivery for in-demand products, the company serves a vast global clientele.

Key Strengths:

In-house R&D center with 30+ patents

ISO 9001 & ISO 14001 certified, compliant with RoHS and BSCI standards

SAP, PLM, and MES systems for production tracking

Core Product Offerings

Neodymium Pot Magnets (Superior holding strength)

Ferrite/Alnico Pot Magnets (Cost-effective & high-temperature resistant)

Rubber-Coated & Countersunk Pot Magnets (Protection against corrosion and impact)

Ideal Applications: Industrial mounting, warehouse management, medical equipment, and promotional displays.

2. Master Magnetics – USA’s Trusted Magnetic Solutions Provider

Headquarters: Pueblo, Colorado, USA | Website: www.magnetsource.com

Company Overview

A mainstay in the magnet industry since 1996, Master Magnetics is a top choice for high-performance neodymium pot magnets in North America. The company emphasizes strong pull force relative to compact sizes, making their products ideal for heavy-duty industrial and commercial uses.

Key Strengths:

Premium-grade NdFeB (Neodymium) Pot Magnets

Customized magnetic assemblies

B2B & retail-friendly distribution model

Popular Products

Countersunk Pot Magnets

Rubber-Coated Magnets (Anti-slip & Scratch-resistant)

Threaded Base Pot Magnets (For mechanical fastening)

Ideal Applications: Workbench fixtures, automotive tool holders, and exhibition displays.

3. Magnet4Sale – Affordable Yet High-Performance Magnets

Headquarters: USA (Global Distribution) | Website: www.magnet4sale.com

Company Overview

Magnet4Sale is a go-to supplier for budget-friendly but reliable pot magnets. Catering to hobbyists, educators, and industrial users, the company offers a diverse catalog with quick shipping ideal for small businesses.

Key Strengths:

Competitive bulk pricing

Straightforward eCommerce experience

Extensive range of pot, cup, and mounting magnets

Best-Selling Products

Heavy-Duty Cup Magnets (For shelving & tool organization)

Magnetic Bases (For machining & industrial setups)

Rubber-Backed Pot Magnets (Non-marring applications)

Ideal Applications: Educational projects, home DIY, and workshop organization.

4. Weizhong Magnetics – Custom Magnetic Solutions

Headquarters: Ningbo, China | Website: www.weizhongmagnetics.com

Company Overview

Weizhong Magnetics specializes in custom pot magnet assemblies, supplying both ferrite and neodymium variants. Since 2018, the company has rapidly grown, partnering with industrial buyers globally.

Key Strengths:

OEM & ODM-friendly (Small MOQs)

High-temperature-resistant magnets (up to 200°C)

Threaded & hook-equipped pot magnet options

Notable Products

Neodymium Pot Magnets with Internal/External Threads

AlNiCo Pot Magnets (For extreme heat environments)

Waterproof Epoxy-Coated Magnets (Marine & outdoor use)

Ideal Applications: HVAC systems, robotics, and automated production lines.

5. Faizeal Magnetic Technology – Cost-Competitive Chinese Manufacturer

Headquarters: Ningbo, China | Website: www.fzmag.com

Company Overview

Ningbo Faizeal is a leading volume supplier to SMEs in North America and Europe. Known for affordable pricing without compromising quality, they offer one of the widest pot magnet selections in China.

Key Strengths:

Bulk discount pricing for resellers

Custom coatings & threading options

Certified (SGS & RoHS compliant)

Top Products

Male/Female Threaded Pot Magnets (For modular assembly)

Hook-Equipped Cup Magnets (Retail displays & signage)

Encapsulated Pot Magnets (Corrosion-resistant)

Ideal Applications: Trade show booths, warehouse signage, and machinery fixtures.

6. Stanford Magnets – Specialty Magnetic Solutions

Headquarters: San Jose, USA | Website: www.stanfordmagnets.com

Company Overview

Focused on ceramic ferrite and rare earth magnets, Stanford Magnets serves high-tech and industrial clients. They provide bespoke pot magnet configurations with stringent quality control.

Key Strengths:

High-precision magnetic assemblies

Military & aerospace-grade products

Fast prototyping services

Key Offerings

Temperature-Stable Pot Magnets

High-Coercivity Ferrite Magnets

Medical & Sensor-Grade Magnetic Solutions

Ideal Applications: Scientific research, defense, and medical devices.

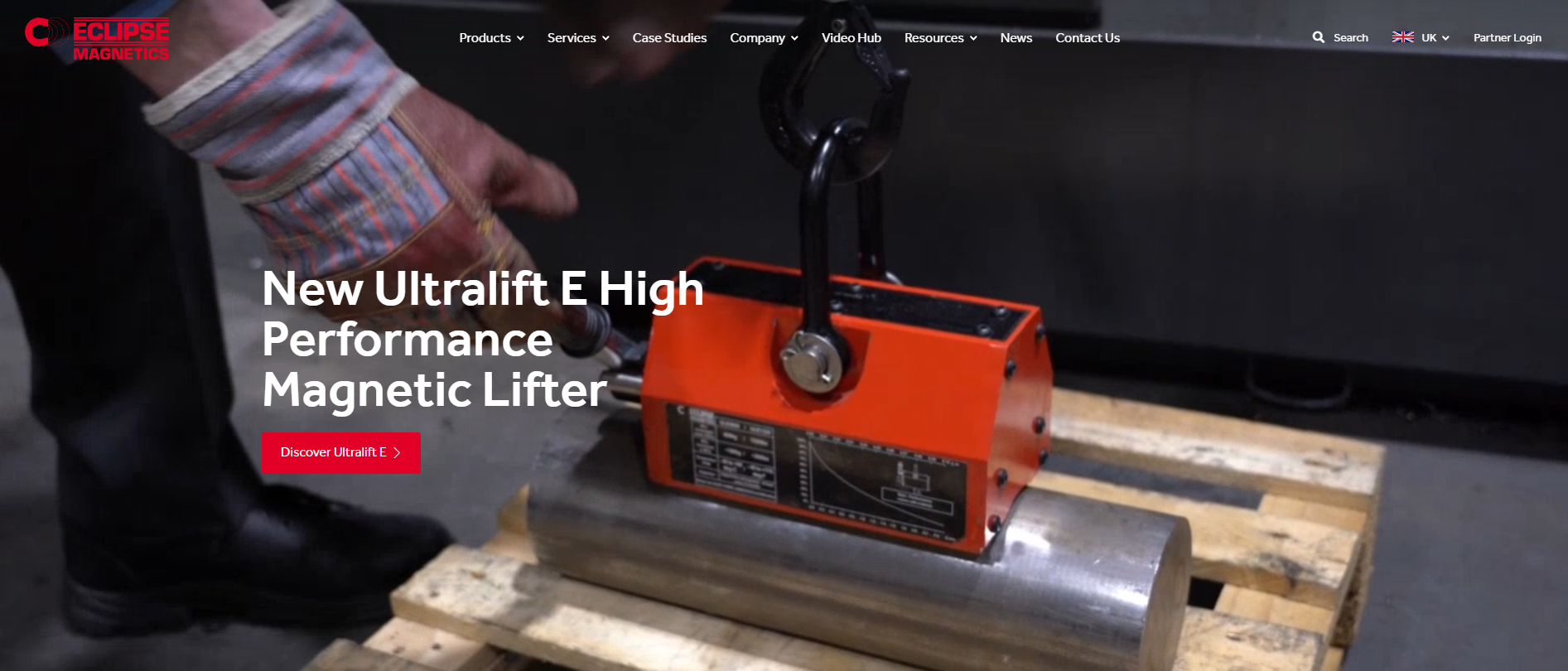

7. Eclipse Magnetics – UK’s Industrial Magnetic Expert

Headquarters: London, UK | Website: www.eclipsemagnetics.com

Company Overview

Eclipse Magnetics is a global leader in heavy-duty clamping magnets, supplying precision-engineered pot magnets for manufacturing & automation.

Key Strengths:

Extreme durability (Industrial-rated)

Internal-threaded deep pot magnets

Hazardous environment compliance (ATEX)

Main Products

Safety-Locked Pot Magnets

Magnetic Workholding Solutions

Custom Magnetic Fixtures

Ideal Applications: CNC machining, woodworking, and high-vibration environments.

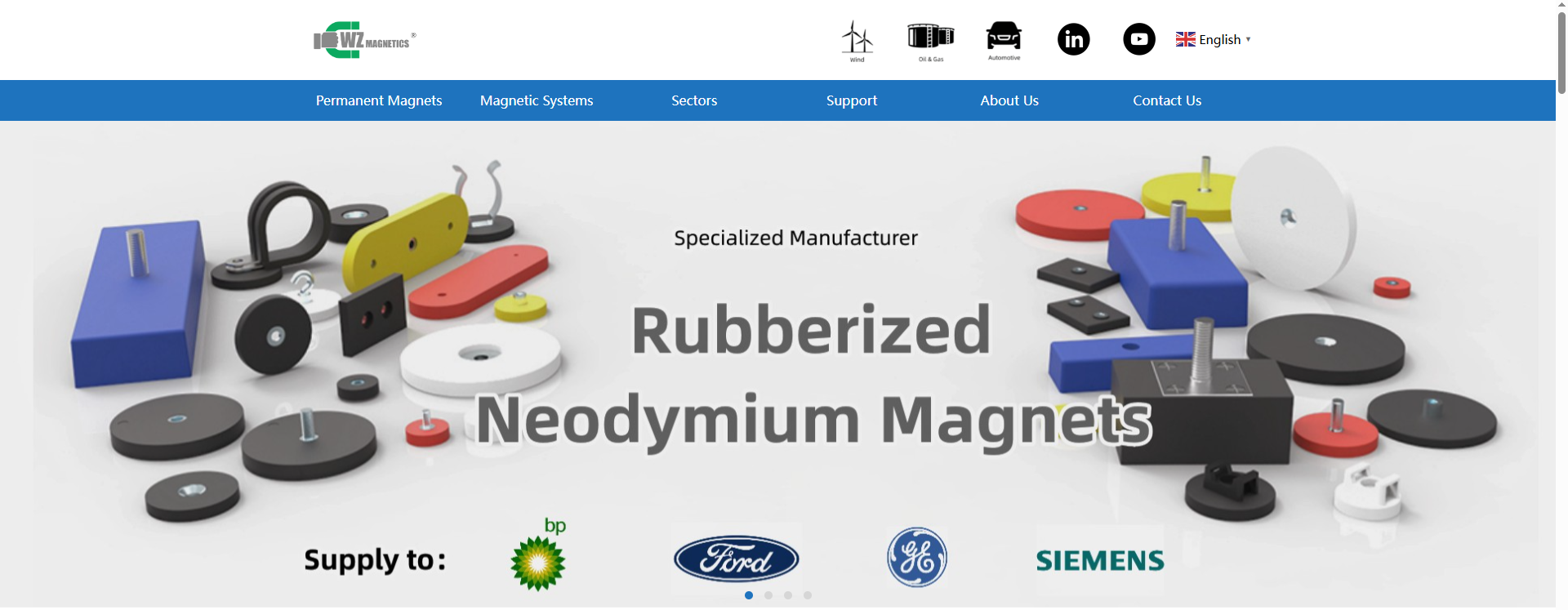

8. WZ Magnetics – Custom-Built Magnetic Assemblies

Headquarters: Shanghai, China | Website: www.wzmagnetics.com

Company Overview

WZ Magnetics specializes in custom-designed pot magnets that meet specific industrial requirements. With flexibility in materials, coatings, and magnetic strength customization, they’re a preferred supplier for automotive, aerospace, and robotics applications.

Key Strengths:

Flexible MOQs (Low minimum order quantities)

Multi-coating options (Nickel, zinc, rubber, epoxy)

Threading & machining services (For specialized mounting)

Main Products:

Tailored Neodymium Pot Magnets

Shallow & Deep Cup Magnets

Magnetic Couplers for Robotics

Best Used For: Automation systems, sensor technology, electric vehicle components.

9. KENENG – High-Strength Custom Pot Magnets

Headquarters: Ningbo, China | Website: www.kenenghardware.com

Company Overview

With over a decade of expertise, KENENG delivers hard-wearing, industrial-grade pot magnets at competitive rates. They focus on OEM & private-label production, making them ideal for bulk buyers and distributors.

Key Strengths:

10+ years in neodymium magnet production

High-stress resistance designs

Multi-layer corrosion protection

Top-Selling Products:

Super Strong N52 Pot Magnets

High-Temperature Alnico Cup Magnets

Magnetic Bases for Jigs & Fixtures

Best Used For: Heavy equipment, assembly lines, magnetic fixtures in construction.

10. Adams Magnetic Products – Specialty & Rare-Earth Magnets

Headquarters: Illinois, USA | Website: www.adamsmagnetic.com

Company Overview

Adams is a US-based innovator in rare earth pot magnets, offering high-performance solutions for demanding industries like medical, military, and energy sectors. Their precision engineering and strict quality control set them apart.

Key Strengths:

Extreme holding power magnets (up to 1,000+ lbs)

Lab & medical-grade magnetic components

Magnetic shielding & consulting services

Key Offerings:

Medical Imaging Pot Magnets (MRI-compatible)

Radiation-Resistant Magnets

Magnetic Latches for Industrial Doors

Best Used For: Defense equipment, renewable energy systems, healthcare devices.

What are the Applications of Pot Magnets

Pot magnets are known for their versatility and high magnetic strength, making them suitable for:

Heavy-Duty Holding: Ideal for securing objects in industrial settings.

Mounting and Fixing: Commonly used in workstations, classrooms, and offices.

Inventory Management: Effective for organizing equipment in warehouses.

Promotional Displays: Securely holding marketing materials in retail environments.

Retrieval: Assisting in the recovery of metal objects.

How Pot Magnets Work

Pot magnets operate by utilizing their magnetic field to attach to ferromagnetic materials. When in contact with iron or steel, the magnetic field interacts with the material's magnetic domains, creating a strong attraction. For non-ferromagnetic materials, pot magnets feature fittings that allow for mechanical attachment, enhancing stability.

Why Choose the Souwest Magnetech Pot Magnet Manufacturer?

1. Optimal Performance

High-grade materials (N52 neodymium, shielded ferrites)

Precision engineering for consistent pull strength

2. Industry Compliance

Meets RoHS, REACH, and ISO certifications

Radiation-resistant options for medical/aerospace use

3. Custom Solutions

Tailored sizes, threading, and coatings

Prototyping support for specialized applications

4. Supply Reliability

Bulk inventory with fast global shipping

No production delays from material shortages

5. Cost Efficiency

Durable coatings (epoxy/zinc) reduce replacements

Volume discounts from wholesale specialists

6. Safety Assurance

Tested for extreme temperatures (-50°C to 200°C)

Military-grade options for critical installations

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية